Offline, Centralized & Feedstock Pre-Blending

TSM Control Systems, your trusted partner in overcoming the complexities of Offline, Centralized & Feedstock Pre-Blending in the plastics industry. With our innovative solutions and a deep understanding of the industry, we are dedicated to helping you navigate through the challenges of quality, durability, cost-effectiveness, and environmental sustainability.

Your Partner for Offline, Centralized & Feedstock Pre-Blending

At TSM Control Systems, we specialize in providing comprehensive solutions for Offline, Centralized & Feedstock Pre-Blending in the plastics industry. Our range of products and services are designed to enhance accuracy, increase productivity, improve quality, and reduce costs.

The plastics industry faces several challenges in implementing Offline, Centralized & Feedstock Pre-Blending. At TSM Control Systems, we’ve designed our solutions to directly address these challenges:

Blending Dissimilar Plastics

Different types of plastics have unique properties, and blending them can be complex. Our Opti-Mix Gravimetric Batch Blending and TSM Multi-Blend systems are designed to handle this complexity, ensuring consistent, high-quality results.

Feedstock Variability

The variability, availability, and affordability of feedstock can pose significant risks. Our Opti-Batch Material Totalizer and Real Time Industry 4.0 IIoT Data Services help manage these risks by tracking material usage and providing real-time data for better decision-making.

Economic Considerations

Implementing a pre-blending process requires careful economic analysis and optimization. Our solutions, including the Opti-Flake High Throughput Blender and Conveying Systems, are designed to increase productivity and efficiency, helping to offset costs.

Regulatory Compliance

Environmental regulations can impact the types of materials used in the blending process and how waste materials are handled. Our Material Pre-Treatment (Drying) systems and Insight Realtime Data Collection help ensure compliance by preparing materials properly and providing real-time data for monitoring and reporting.

Technological Challenges

Developing new recycling lines and integrating them into existing operations can be technologically challenging. Our team of experts provides full support, from the delivery and installation of equipment to staff training, ensuring a smooth transition.

By addressing these challenges head-on, TSM Control Systems empowers businesses in the plastics industry to improve the quality and consistency of their products while increasing efficiency and reducing costs.

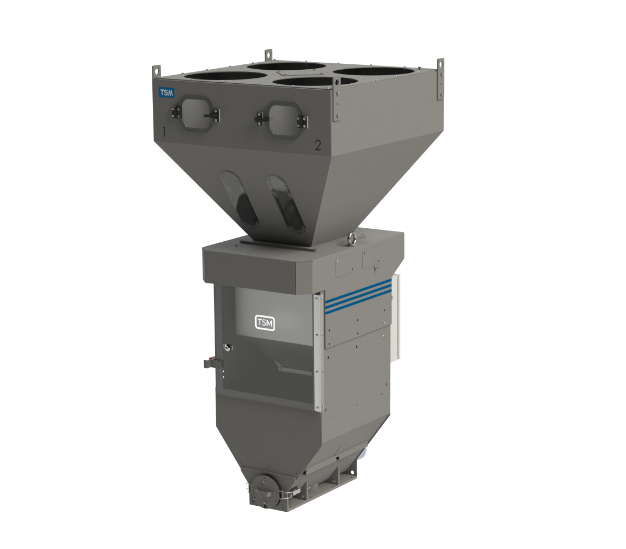

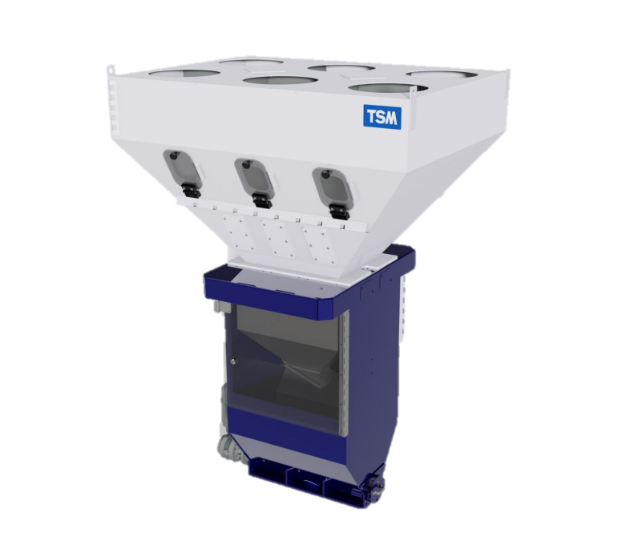

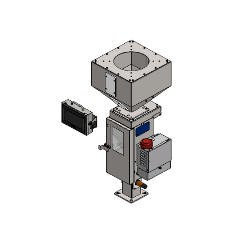

Opti-Mix Gravimetric Batch Blending

Our Opti-Mix system ensures precise measurement and blending of materials by weight, guaranteeing consistency and quality in your final product.

Opti-Flake High Throughput Blender

Designed for high-volume operations, this blender can handle large quantities of material, increasing productivity and efficiency.

TSM Multi-Blend

Our Multi-Blend solution allows for the blending of multiple materials, providing flexibility and versatility in your production process.

Opti-Batch Material Totalizer

This system tracks and manages the total amount of material used in the blending process, aiding in inventory management and cost control.

Conveying Systems

Our conveying systems transport materials from one location to another, facilitating efficient workflow in your production process.

Material Pre-Treatment (Drying)

Our pre-treatment process prepares materials for blending by removing moisture, which can affect the quality of the final product.

Insight Realtime Data Collection

Our Insight system collects and analyzes data in real time, providing valuable insights for process optimization and quality control.

Real Time Industry 4.0 IIoT Data Services

Leveraging the power of the Industrial Internet of Things (IIoT), we provide real-time data and analytics, enabling predictive maintenance, process optimization, and improved operational efficiency.

Our solutions offer numerous benefits, including:

- Increased Accuracy: Our gravimetric blenders ensure precise measurement and blending of materials.

- Increased Productivity: Our high-throughput blenders and conveying systems enhance your production capacity.

- Improved Quality: Our pre-treatment systems and real-time data collection improve the quality of your products.

- Reduced Costs: Our material totalizer and IIoT data services help reduce costs by optimizing material usage and predictive maintenance.

Why Choose TSM Control Systems to assist you in Offline, Centralized & Feedstock Pre-Blending?

Choosing TSM Control Systems to assist in your Offline, Centralized & Feedstock Pre-Blending process means you’re opting for a partner committed to delivering high-quality, efficient, and sustainable solutions. Here’s why TSM Control Systems stands out as a trusted choice:

- Expertise

- Innovation

- Customization

- Sustainability

- Quality Assurance

- Excellent Customer Support

- Global Presence

By choosing TSM Control Systems, you’re investing in a partnership that brings industry-leading technology, unparalleled expertise, and unwavering support to your Offline, Centralized & Feedstock Pre-Blending operations. Our mission is to provide you with the tools and solutions that will drive your operational efficiency, product quality, and ultimately, your business success.

Request a Quote

Are you a project engineer looking for a solution which avoids downtime but is customizable to your needs? TSM has the resources for any project, along with the expertise in delivering world class service and support. For quality products delivered on time and in budget, get in touch with TSM today to learn more.