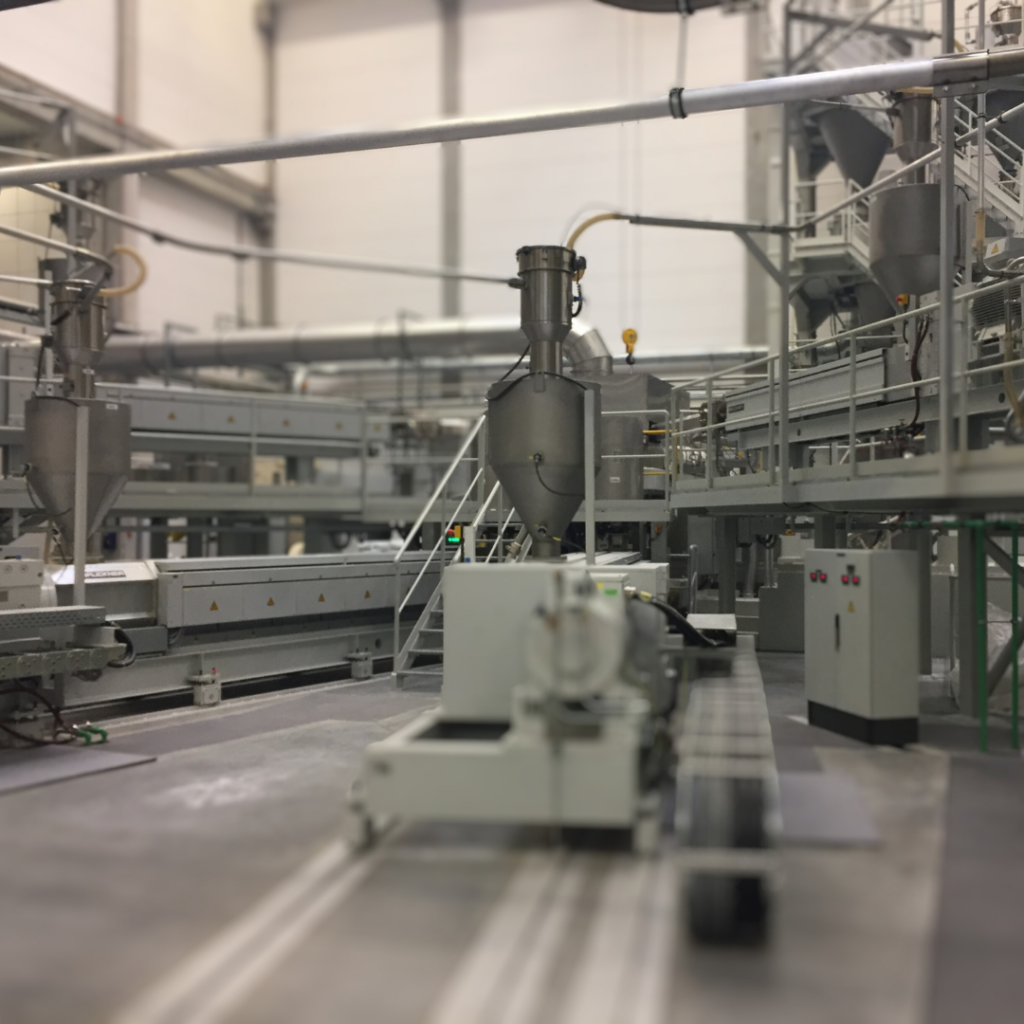

BOPP Extrusion

TSM Control Systems, your trusted partner in overcoming the complexities of BOPP film production. With our innovative solutions and a deep understanding of the industry, we are dedicated to helping you navigate through the challenges of quality, durability, cost-effectiveness, and environmental sustainability in the BOPP industry.

TSM Control Systems – Your Solution for BOPP Extrusion

At TSM Control Systems, we understand the unique challenges of the BOPP industry – from maintaining consistent quality and durability of films to managing high production costs and environmental impact. Our cutting-edge gravimetric blenders, control systems, and troubleshooting services are designed to optimize your BOPP film production. By enhancing quality, increasing productivity, reducing costs, and minimizing environmental impact, we help you stay competitive and sustainable in the global marketplace.

Addressing the Challenges in the BOPP Industry

The BOPP industry is confronted with numerous challenges that impact the quality, durability, cost-effectiveness, and environmental sustainability of BOPP film production. These include:

- Quality: Inconsistencies in the quality of BOPP film often arise from variations in the materials used, the manufacturing process, and the conditions in which the film is used. These inconsistencies can lead to film breakage, cloudiness, and poor printability.

- Durability: BOPP film can be vulnerable to damage from UV rays, chemicals, and abrasion, shortening the film’s lifespan and necessitating premature replacement.

- Cost: The higher cost of BOPP film compared to other film types can make it prohibitive for certain applications, such as budget-conscious packaging.

- Environmental Impact: The production of BOPP film can negatively impact the environment due to the use of chemicals and energy in the manufacturing process, and the disposal of waste materials

TSM Control Systems offers innovative solutions to tackle these challenges, improving the quality, durability, cost-effectiveness, and environmental sustainability of BOPP film production.

- Gravimetric Blenders: Our gravimetric blenders accurately and consistently blend the various materials used in making BOPP film. This enhances the quality of the film and reduces waste generated during manufacturing.

- Control Systems: Our control systems monitor and control the extrusion process in real time, enabling early identification and resolution of problems. This prevents potential damage to the film and production downtime.

Here’s how TSM Control Systems can address these challenges:

- Improved Quality: By ensuring consistent blending and mixing of materials, our products and services enhance the quality of BOPP film.

- Increased Productivity: Our efficient material delivery to the extruder shortens the production cycle and lowers costs, enhancing productivity.

- Reduced Costs: By minimizing waste and improving the yield from the extrusion process, we help reduce production costs, leading to a more profitable business.

- Better Troubleshooting: Our troubleshooting services enable quick problem identification and resolution, reducing downtime and improving overall production efficiency.

- Reduced Environmental Impact: Our products and services reduce the environmental impact of BOPP film production through the use of more sustainable materials and by reducing waste generated in the manufacturing process.

At TSM Control Systems, we provide innovative solutions designed to enhance your BOPP film production. Our offerings include:

Opti-Mix Gravimetric Blenders

- Precision and Consistency: Our Opti-Mix Gravimetric Blenders ensure precise and consistent blending of materials, enhancing the quality of your BOPP extrusion processes.

- Efficiency: Our technology reduces waste and improves the yield of the extrusion process, leading to significant cost savings.

Material Pre-Treatment Solutions

- Effective Drying and Optimal Conditioning: Our systems ensure effective drying and optimal conditioning of your materials, reducing moisture content and maximizing end-product quality.

- Energy Efficiency: Our pre-treatment solutions are designed for energy efficiency, aligning with your sustainability goals.

Conveying Solutions

- Efficient Material Transport: Our conveying systems offer efficient and seamless material transport, reducing manual labor and minimizing downtime.

- Reliability and Durability: Engineered for reliability and durability, our conveying systems withstand the demands of your material handling needs.

Why Choose TSM Control Systems to assist you in BOPP Extrusion?

Choosing TSM Control Systems to assist in your BOPP extrusion process means you’re opting for a partner committed to delivering high-quality, efficient, and sustainable solutions. Here’s why TSM Control Systems stands out as a trusted choice:

- Expertise

- Innovation

- Customization

- Sustainability

- Quality Assurance

- Excellent Customer Support

- Global Presence

By choosing TSM Control Systems, you’re investing in a partnership that brings industry-leading technology, unparalleled expertise, and unwavering support to your BOPP extrusion operations. Our mission is to provide you with the tools and solutions that will drive your operational efficiency, product quality, and ultimately, your business success.

Request a Quote

Are you a project engineer looking for a solution which avoids downtime but is customizable to your needs? TSM has the resources for any project, along with the expertise in delivering world class service and support. For quality products delivered on time and in budget, get in touch with TSM today to learn more.