Cast Extrusion

Welcome to TSM Control Systems’ Cast Extrusion page. We specialize in optimizing the complex cast extrusion process with our innovative solutions. Explore our offerings to enhance your operations, improve product quality, and boost efficiency.

Cast Extrusion

At TSM Control Systems, we comprehend the intricacies of cast extrusion and the challenges that emerge in the production process. We offer state-of-the-art solutions that not only meet but exceed your processing needs. TSM Control Systems: Your solution for advanced cast extrusion applications.

- Material Handling: Ensuring homogeneous blending of materials, managing multiple recipes, and precise dosing of additives is no small task. The lack of precision can lead to quality issues in the final product.

- Energy Efficiency: The pressure to reduce energy consumption without compromising production quality or throughput is a significant concern. High energy costs can impact the overall profitability of operations.

- Inventory Management: Accurate tracking of material usage and inventory control is critical to avoid production downtime and maintain operational efficiency.

- Downtime Reduction: Every moment your machines aren’t running due to maintenance, cleaning, or recipe changes is a moment of lost productivity.

- Opti-Mix Gravimetric Batch Blending: This system accurately blends multiple materials by weight in batches. It ensures the correct proportions of different materials are combined, which is crucial for producing high-quality plastic films in the cast extrusion process. The Opti-Mix system can handle a wide range of materials and is designed for easy cleaning and maintenance.

- Optix LIW Gravimetric Batch Blending: Similar to the Opti-Mix, this system also blends materials by weight, but it uses a loss-in-weight (LIW) method. This means it continuously weighs the material in the hopper and adjusts the feed rate to maintain the desired blend ratio. This can provide more precise control over the blending process, especially for complex or sensitive materials.

- Opti-Blend MLIW Continuous Gravimetric Dosing (Flood Fed): This system provides continuous, weight-based blending of materials. The “flood fed” designation suggests it’s designed to handle a high volume of material. It uses a multi-component loss-in-weight (MLIW) method to maintain the desired blend ratio, even as the material is being used in the extrusion process.

- Opti-Yield SLIW Extruder Control: This system optimizes the extrusion process by controlling factors like the speed and temperature of the extruder. It uses a single-component loss-in-weight (SLIW) method to monitor the material usage in real-time and adjust the extruder settings to optimize the yield and quality of the final product.

- Conveying Systems: These systems handle the movement of materials in the production process. They can include vacuum conveyors, pneumatic conveyors, and other equipment necessary for managing raw materials and finished products. TSM’s conveying systems are designed for reliability and efficiency, reducing the risk of material loss or contamination.

- Material Pre-Treatment (Drying): This refers to equipment or processes used to prepare raw materials for extrusion. TSM’s drying systems remove moisture from plastic pellets, which can improve the quality of the final product and prevent issues like bubbles or defects in the plastic film.

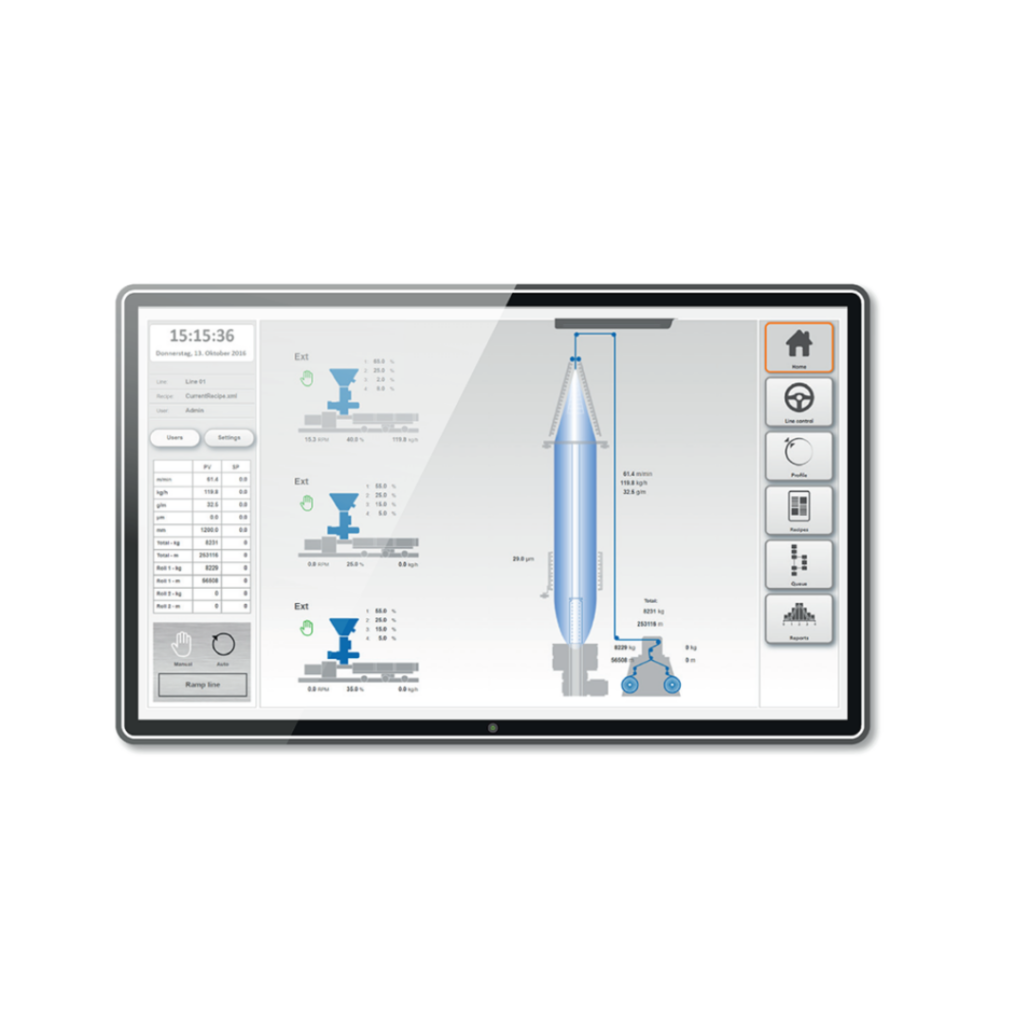

- Supervisory Systems: These systems oversee and manage the entire production process. They can monitor equipment status, schedule production runs, track product quality, and more. TSM’s supervisory systems are designed for easy integration with existing equipment and can provide valuable data for improving efficiency and reducing waste.

- Layer Ratio Control: This system controls the thickness of individual layers in a multilayer film. This can be important for producing films with specific properties or characteristics. TSM’s layer ratio control system provides precise control over each layer, ensuring consistent quality across the entire film.

- Automatic Extruder / Yield Control: This system automatically adjusts the extrusion process to optimize the yield, or amount of usable product produced. It can control factors like the extruder speed, temperature, and pressure, and it can adjust these settings in real-time based on the current conditions and material properties.

- Insight Realtime Data Collection: This technology allows for real-time monitoring and adjustments in the production process. It can collect data on a wide range of parameters, including material usage, equipment status, product quality, and more. This data can be used for immediate feedback and control, as well as for long-term analysis and process improvement.

- Real Time Industry 4.0 IIoT Data Services: This refers to advanced, internet-connected systems that collect and analyze data from the production process. These systems can provide real-time insights and alerts, as well as historical data for trend analysis and predictive maintenance. TSM’s IIoT services are designed for easy integration with existing equipment and can provide valuable insights for improving efficiency, reducing waste, and maintaining product quality.

-

Advanced Blending Systems: Our Opti-Mix and Optix LIW Gravimetric Batch Blending systems ensure precise and homogeneous blending of materials, crucial for high-quality cast extrusion.

-

Continuous Gravimetric Dosing: The Opti-Blend MLIW system provides continuous, weight-based blending of materials, handling high volumes of material with ease.

-

Extruder Control: Our Opti-Yield SLIW system optimizes the extrusion process, controlling factors like the speed and temperature of the extruder for improved efficiency and product quality.

-

Comprehensive Material Handling: From conveying systems to material pre-treatment (drying), we offer a full suite of solutions for efficient material handling.

-

Real-Time Data Collection: With our Insight and Industry 4.0 IIoT Data Services, monitor your production process in real-time for immediate feedback and control.

-

Improved Product Quality: Our advanced blending and control systems ensure consistent, high-quality output in the cast extrusion process.

-

Enhanced Efficiency: From material handling to extruder control, our solutions are designed to optimize every aspect of the cast extrusion process for maximum efficiency.

-

Energy Savings: Our systems are designed with energy efficiency in mind, helping to reduce your operation’s energy consumption and costs.

-

Reduced Downtime: Our solutions help to minimize downtime, whether from maintenance, cleaning, or recipe changes, keeping your production running smoothly.

-

Customizable Solutions: We understand that every operation is unique. Our systems are customizable to meet your specific needs, ensuring the best fit for your process.

-

Global Support: With our global presence, we offer excellent customer support wherever you are, ensuring you get the help you need when you need it.

Why Choose TSM Control Systems to assist you in Cast Extrusion?

Choosing TSM Control Systems for your cast extrusion process means you’re opting for a partner committed to delivering high-quality, efficient, and sustainable solutions. Here’s why TSM Control Systems stands out as a trusted choice:

- Expertise

- Innovation

- Customization

- Sustainability

- Quality Assurance

- Excellent Customer Support

- Global Presence

By choosing TSM Control Systems, you’re investing in a partnership that brings industry-leading technology, unparalleled expertise, and unwavering support to your cast extrusion operations. Our mission is to provide you with the tools and solutions that will drive your operational efficiency, product quality, and ultimately, your business success.

Request a Quote

Are you a project engineer looking for a solution which avoids downtime but is customizable to your needs? TSM has the resources for any project, along with the expertise in delivering world class service and support. For quality products delivered on time and in budget, get in touch with TSM today to learn more.