8 Must-Have Tips for Processing Low Bulk Density Materials

Processing low bulk density materials, such as powders and granules, can present a number of challenges for plastic processors. Follow…

In a world actively striving for sustainability, Cherry Pipes has set out to redefine waste management by transforming it into a vital component of their sustainable plastic processing operations. A significant catalyst in this transformative journey has been their collaboration with TSM Control Systems, a global leader in pre-feeding solutions for the recycling industry.

Cherry Pipes aimed to repurpose waste plastic from one facility by converting it into flake, which would be reintegrated into their production process. This complex endeavor required advanced pre-feeding solutions to lay the groundwork for the subsequent stages of the recycling process.

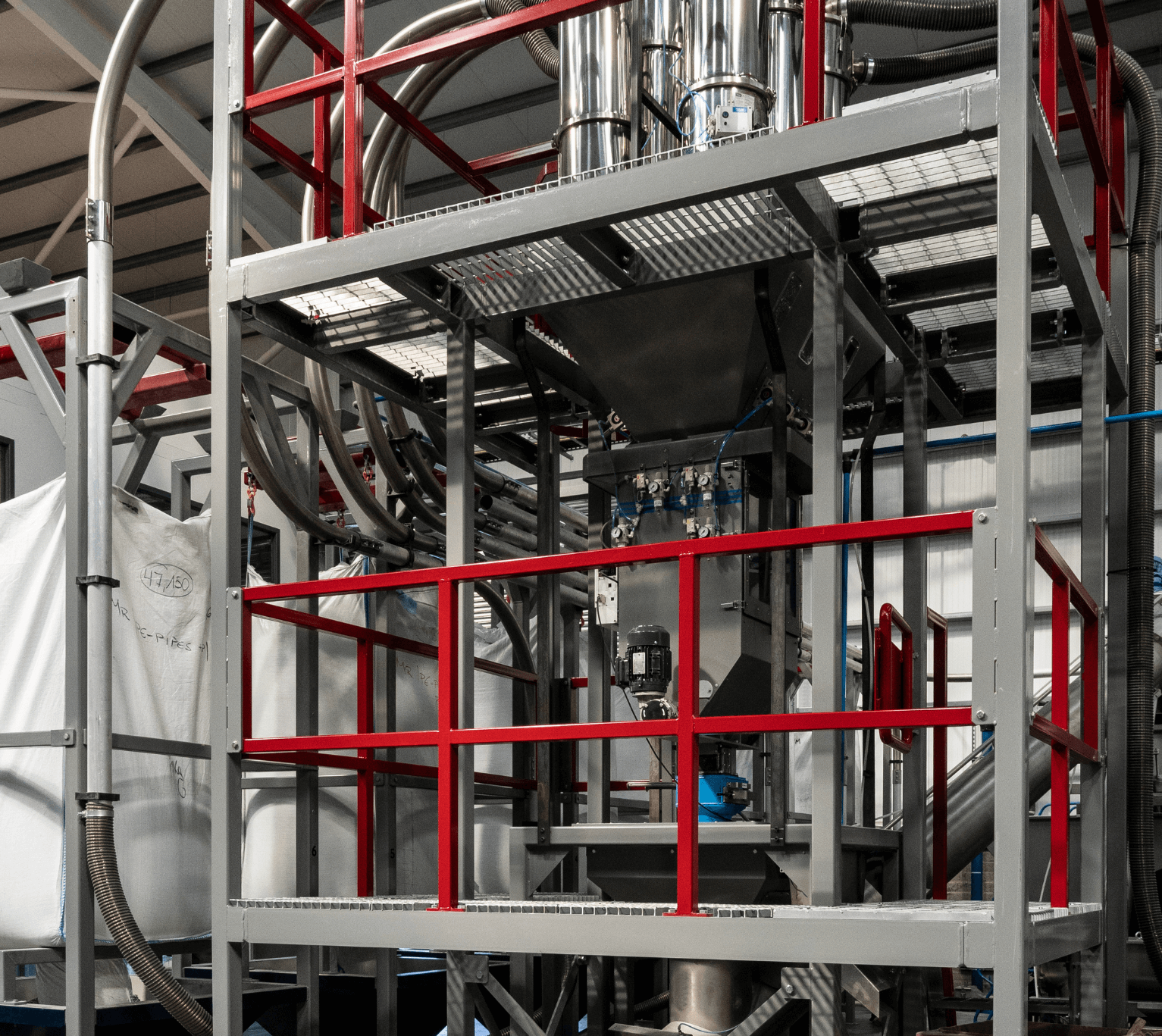

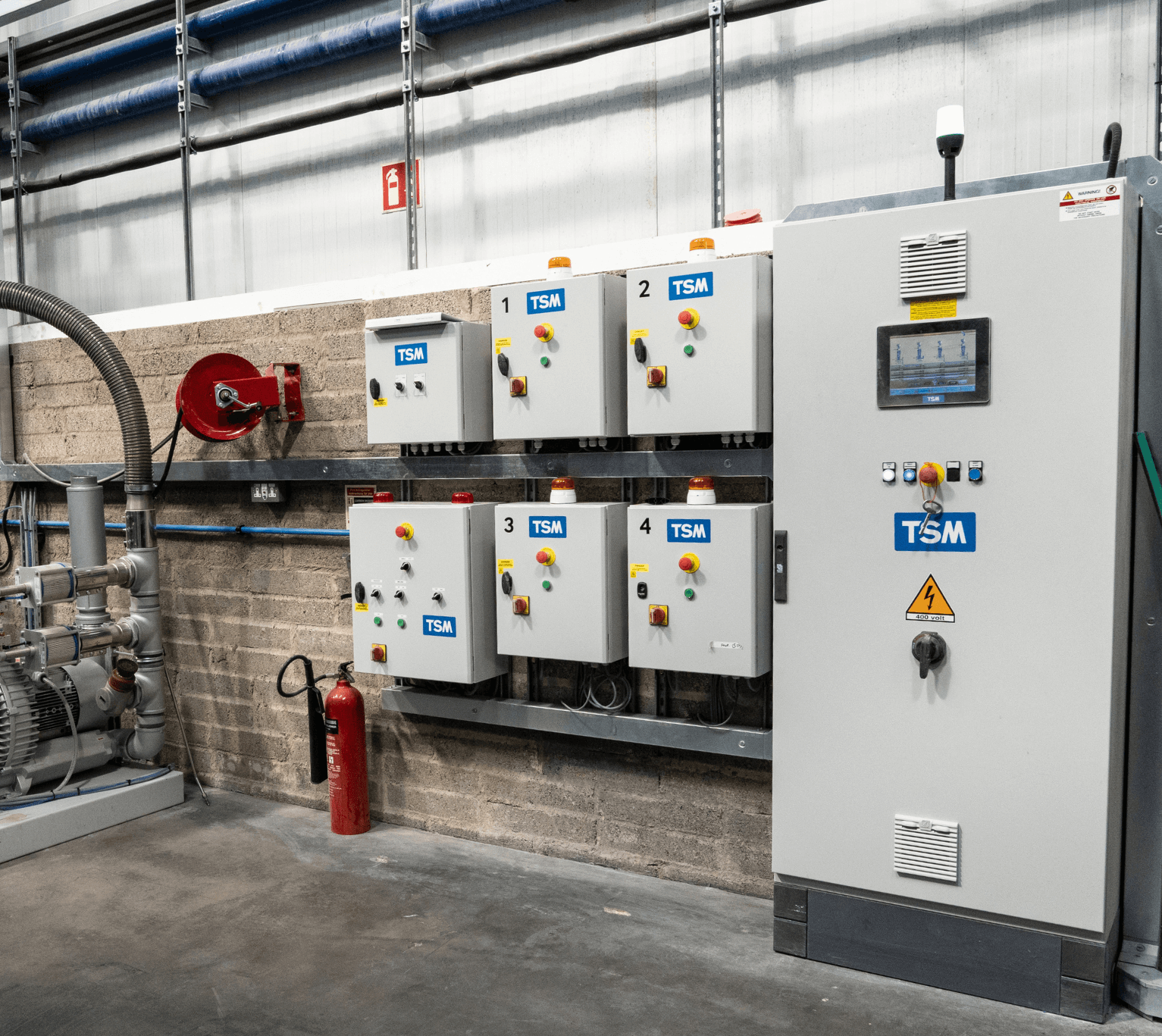

Utilizing their industry-leading expertise in pre-feeding solutions, TSM Control Systems provided Cherry Pipes with a highly specialized and customized system. The core of this system was the Opti-Mix Gravimetric Blender, which utilized TSM’s patented reverse flight auger mixing technology to:

View all our images on our recent case study at the bottom of the page.

In addition to the blending solution, TSM engineered a custom conveying system designed to handle lightweight and fluffy recycled materials, significantly reducing production time and costs.

Allen Cherry, Site Manager at Cherry Pipes, had this to say about the collaboration:

“Our new recycling line isn’t just about waste management; it’s a vital cog in our sustainable plastic processing operation. It’s a crucial step toward fulfilling our commitment to sustainability and operational excellence.”

Video:

The newly implemented recycling line has significantly boosted Cherry Pipes’ operational efficiency and contributed to their sustainability goals. Achieving a 20% boost in recycling efficiency and a 15% drop in energy consumption.

The collaboration between Cherry Pipes and TSM Control Systems doesn’t just spell efficiency and cost-effectiveness; it also contributes significantly to environmental preservation by reducing waste and curbing harmful emissions.

With the power of TSM Control Systems’ pre-feeding solutions and Cherry Pipes’ commitment to sustainability, this collaboration serves as a beacon for what’s possible in the ever-evolving landscape of recycling and sustainability.

The newly implemented recycling line has significantly boosted Cherry Pipes’ operational efficiency and contributed to their sustainability goals.

Interested in achieving similar results for your organization? Contact us today to learn how TSM Control Systems can help you meet your sustainability and operational goals.

Check out our latest cases studies.