The Evolution of Plastic Extrusion: The Pivotal Role of TSM Control Systems

As a continually evolving sphere, the manufacturing industry has witnessed the plastics sector emerge as a constant symbol of relentless innovation. Situated at the heart of this evolution is plastic extrusion, a high-volume manufacturing process of immense significance. This article aims to provide an in-depth exploration of the journey of plastic extrusion, underlining particularly the critical role played by TSM Control Systems.

To visualize this transformation more impactfully, refer to our company’s timeline infographic below.

TSM Control Systems Innovative Journey

The Dawn of Plastic Extrusion

Plastic extrusion, with its roots dating back to the late 19th century, has seen significant progression. This evolution, fueled by the advent of advanced machinery and the development of unique polymers, continues to this day, as illustrated in our infographic.

TSM Control Systems: Catalyzing Change in Plastic Extrusion

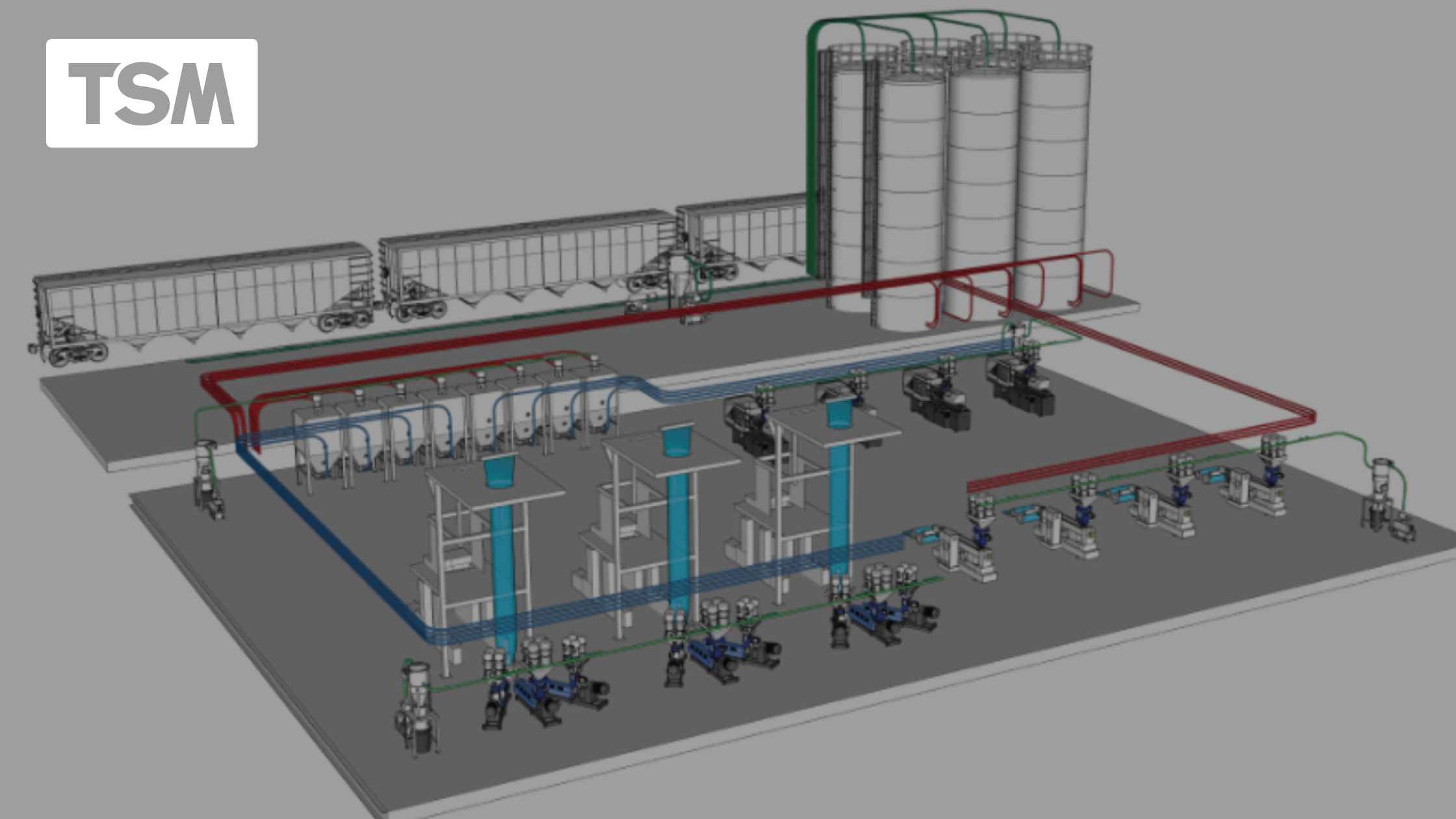

For over four decades, we at TSM Control Systems have played a pivotal role in reshaping the plastic extrusion landscape. Our dedication to the design, development, and manufacturing of gravimetric and materials handling equipment has ignited industry-wide innovation.

Our infographic chronicles key milestones, such as the launch of a new width gauging system in 1979, which brought unprecedented precision to the extrusion process. This innovation was followed by a novel extrusion control system in 1987, which further refined the process and elevated the quality of the end products.

TSM Control Systems Innovative Journey

Revolutionizing Plastic Extrusion with TSM’s Precision Feeding and Blending Systems

Our precision feeding and blending systems, as highlighted in our infographic, have brought about a revolution in plastic extrusion. These systems have not only elevated product quality but also minimized waste by ensuring precise control over material mixes. As a result, they have set the stage for the creation of increasingly complex and varied plastic products.

Embracing Industry 4.0 with the Advent of TSM’s Insight

In alignment with the Industry 4.0 revolution, we introduced Insight, a specialized division at TSM. Insight harnesses the power of the Industrial Internet of Things (IIoT), augmented reality, and rapid prototyping technologies to provide manufacturers with real-time data and improved operational efficiency.

Insight has morphed conventional machinery into intelligent, interconnected systems, offering plastic processors unprecedented insight into the production process. This evolution has facilitated more informed decision-making and boosted productivity.

The Future of Plastic Extrusion and Industry 4.0

Our timeline of innovation demonstrates our unwavering commitment to shaping the future of plastic extrusion. Our conviction in the transformative potential of Industry 4.0 technologies suggests a future where the plastics industry evolves from mere machine building to delivering smart, integrated solutions.

Conclusion

From its humble beginnings to its current sophisticated state, the journey of plastic extrusion stands as a testament to the power of technological innovation. As our infographic illustrates, we at TSM Control Systems continue to spearhead advancements in this field, paving the way for a future of plastic extrusion that’s smarter, more efficient, and sustainable.

Our precision feeding and blending systems have not just refined the plastic extrusion process but also laid the groundwork for a new era in the plastics industry. Our commitment to innovation and our vision for a connected, data-driven manufacturing landscape will undeniably continue to drive the evolution of plastic extrusion in the future.