Gravimetric Batch Blending Explained

A Precise and Efficient Manufacturing Process

Gravimetric Batch Blending is a process used in manufacturing to mix multiple components in a precise ratio, producing a homogeneous mixture or blend. It is commonly used throughout multiple industries and most notably the plastics industry globally.

What is Gravimetric Batch Blending?

The basic principle of Gravimetric Batch Blending involves measuring and weighing each component separately and then combining them in a mixer or blending chamber. The weights of the individual components are carefully controlled to ensure that the correct proportion of each is added to the mix. This process can be automated using specialized equipment that automatically weighs and dispenses each component, ensuring high accuracy and repeatability.

The Gravimetric Batch Blending Process

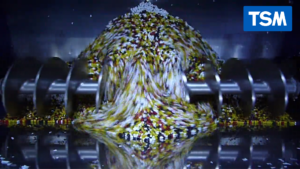

In Gravimetric Batch Blending, each component is typically stored in a separate hopper or container, which is connected to a weighing system. The weighing system measures the weight of the component as it is dispensed into the mixing chamber. Once all the components have been added, they are mixed together until a homogeneous mixture is achieved.

The process involves the following steps:

- Gather and prepare the materials: The materials to be blended are typically stored in separate containers or silos. Each container is equipped with a weighing system that can measure the weight of the material inside.

- Program the blending system: The blending system is programmed with the recipe for the desired mixture. This recipe includes the proportions of each material and the total weight of the batch.

- Weigh the materials: The blending system sequentially measures the weight of each material, starting with the first material in the recipe. The system will stop measuring when it has reached the correct weight for each material.

- Mix the materials: Once all the materials have been weighed, they are combined in a mixer or blender. The mixing process ensures that the materials are evenly distributed.

- Verify the mixture: The final mixture is tested to verify that it meets the desired quality specifications. If the mixture does not meet the requirements, adjustments can be made to the recipe or the process.

Benefits of Gravimetric Batch Blending

The advantages of Gravimetric Batch Blending include high accuracy and consistency, efficient use of materials, and the ability to quickly adjust the mixture ratios to achieve desired product properties. Additionally, this process reduces waste by allowing manufacturers to use only the amount of materials required for each batch, reducing material costs and minimizing environmental impact.

Applications that Use Gravimetric Batch Blending

Gravimetric batch blending plays a vital role in various applications within the plastic processing industry. Here’s how the technique is applied to the specific processes you mentioned:

- Injection Molding: Gravimetric batch blenders ensure precise and consistent blending of raw materials, additives, and colorants before they are fed into the injection molding machines, leading to plastic parts with uniform quality, appearance, and performance.

- Blown Film: In blown film production, gravimetric batch blending is used to mix materials, additives, and colorants for the extrusion process, which forms a continuous film. This ensures consistent film thickness, mechanical properties, and optical characteristics.

- Sheet Extrusion: Gravimetric blenders help create accurate material blends for sheet extrusion processes, which involve melting and forming plastic materials into continuous sheets. This ensures uniform thickness, surface properties, and overall quality of the extruded sheets.

- Extrusion Coating: Gravimetric batch blending is used to combine plastic resins, additives, and colorants for extrusion coating processes, where a thin plastic layer is applied to a substrate, such as paper, fabric, or metal foil. This ensures consistent coating thickness and properties.

- Cast Extrusion: In cast extrusion, gravimetric batch blending is used to mix materials and additives to create a specific blend, which is then fed into an extruder to form a continuous film or sheet. The process ensures consistent thickness, surface properties, and performance of the final product.

- Wire & Cable Extrusion: Gravimetric blenders are employed in wire and cable extrusion to create precise blends of insulating and jacketing materials, ensuring uniform thickness, electrical properties, and overall quality of the extruded cables and wires.

- Compounding / Recycling Lines: Gravimetric batch blending is used in compounding and recycling processes to accurately mix recycled plastics with virgin materials, additives, and colorants, ensuring the desired properties and consistency in the final recycled plastic products.

- Extrusion Blow Molding: Gravimetric batch blenders help create accurate material blends for extrusion blow molding processes, ensuring consistent quality, appearance, and performance of the resulting hollow plastic parts, such as bottles and containers.

- Pipe & Profile Extrusion: In pipe and profile extrusion processes, gravimetric batch blending is employed to mix plastic materials, additives, and colorants to create the desired material blend. This ensures consistent dimensions, mechanical properties, and appearance of the extruded pipes and profiles.

- Multifilament Line (Fiber): Gravimetric batch blending is used in multifilament fiber production to create accurate and consistent material compositions, ensuring the desired properties such as strength, elasticity, and color in the final synthetic fibers and filaments.

- BOPP Extrusion: In biaxially oriented polypropylene (BOPP) film extrusion, gravimetric batch blending helps mix materials and additives to create a specific blend, which is then extruded and stretched in two directions to improve mechanical properties. The blending ensures consistent thickness, clarity, and barrier properties of the BOPP films.

- Offline, Centralized & Feedstock Pre-Blending: Gravimetric batch blenders can be used in offline, centralized, and feedstock pre-blending systems to create consistent material blends before they are introduced into various plastic processing equipment. This ensures accurate and efficient dosing of materials, additives, and colorants, leading to uniform product quality across different production lines.

Conclusion

Gravimetric Batch Blending is a highly accurate and reliable process that is commonly used in various industries to produce a wide range of products, from simple blends to complex formulations, with consistent quality and efficiency. It is an automated process that can be customized to meet the specific requirements of each product.

Our Specialty

TSM Control Systems is a leading manufacturer of Gravimetric Batch Blenders, providing advanced solutions for the precise weighing and mixing of materials in the manufacturing process. Our equipment is designed to handle a wide range of materials and can be customized to meet the specific needs of each industry.

The ever-increasing costs for polymers and additives mean it has never been more important to ensure materials are dosed accurately and are homogenously mixed. The TSM gravimetric batch blender solves this problem due to its unique patented mixing system and slide gate technology.

For more information on our Gravimetric Batch Blenders visit: https://tsm-controls.com/gravimetric-blenders/ or contact us at [email protected]