Blown Film

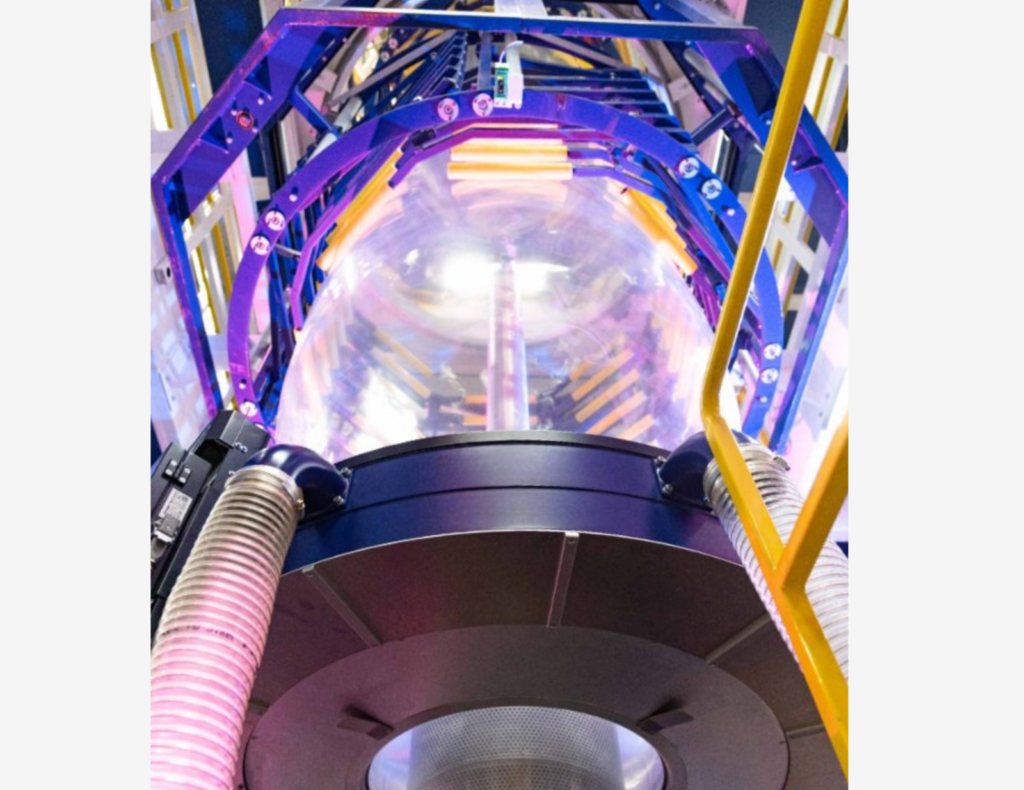

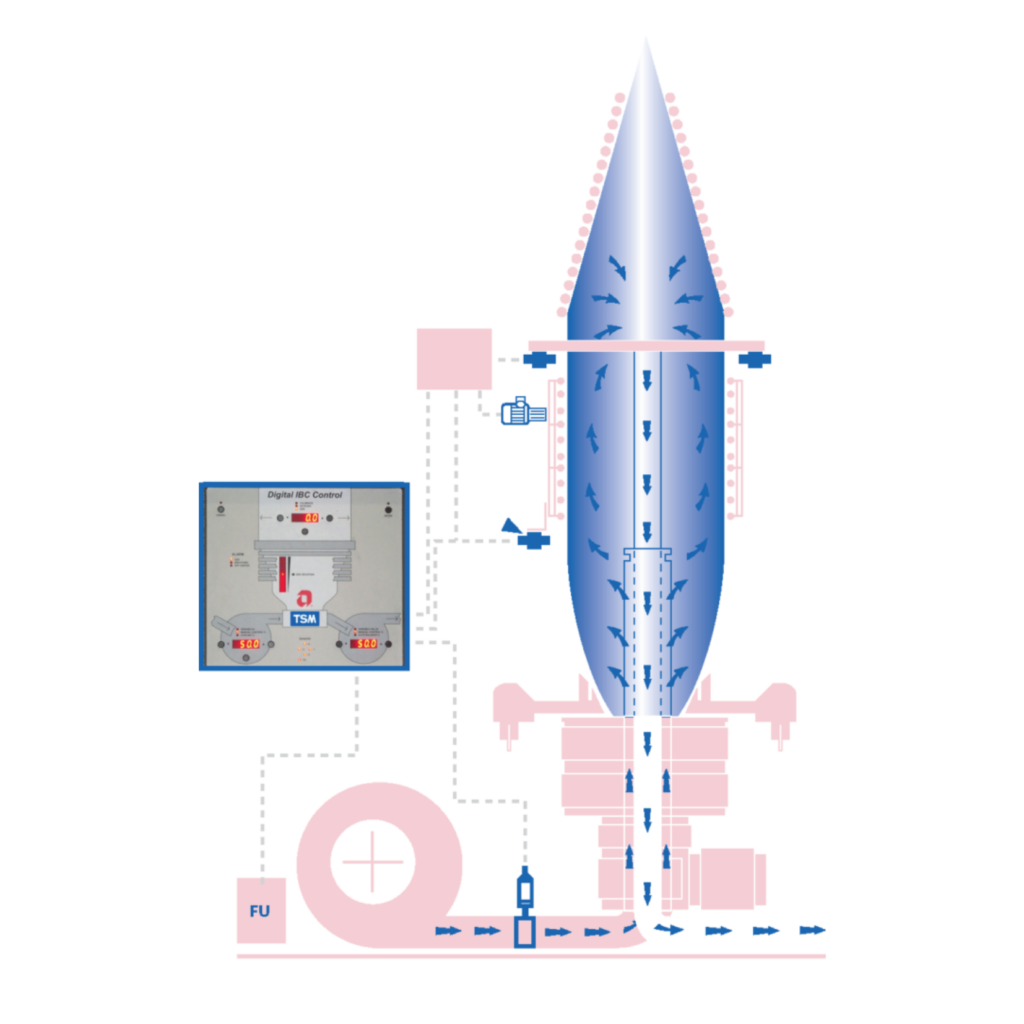

Blown film extrusion is a pivotal process in the plastics industry, especially in the production of plastic films. From packaging materials to agricultural films, the products derived from this process are integral to numerous sectors.

Blown Film Extrusion: Advancing Sustainability and Efficiency in Plastics

As the industry moves towards a more sustainable future, novel technologies and strategies are needed to address the inherent challenges in the blown film industry. One of the critical challenges is the lack of homogeneity in plastic materials, particularly when incorporating recyclates, which can lead to inconsistent product quality. This is where TSM Control Systems steps in, offering innovative solutions that enhance the quality, efficiency, and sustainability of the blown film process.

Download Brochure

DownloadToday, blown film processors face various challenges. One of the significant issues is the inconsistency of plastic materials, particularly when incorporating recyclates. The quality of recyclates can vary widely, leading to problems with material segregation and the consequent non-homogeneity of the end product. The changing regulatory environment, which is increasingly promoting the use of recycled materials, further amplifies these challenges.

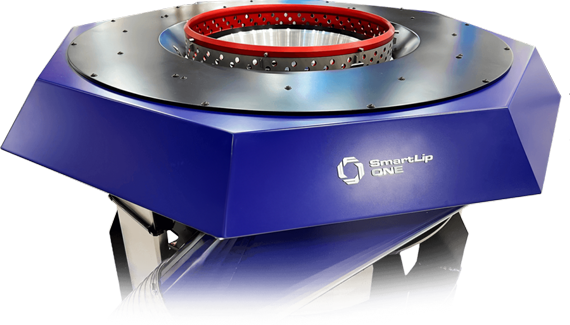

In the realm of blown film extrusion, TSM Control Systems stands out due to several key differentiators:

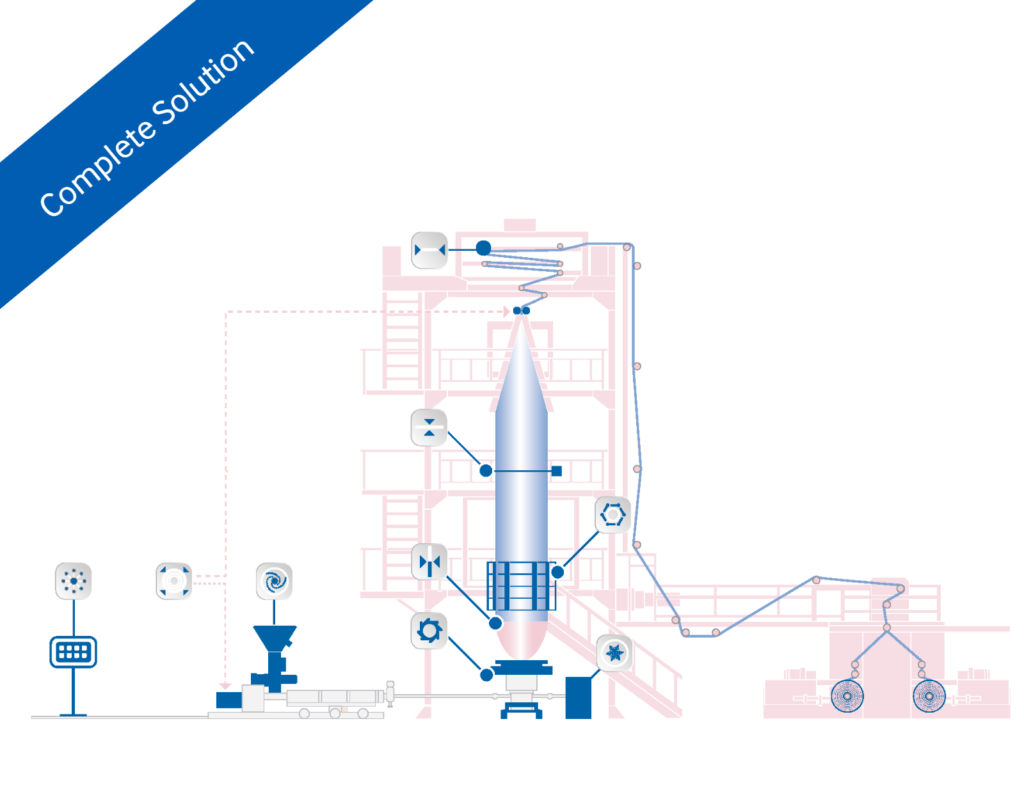

- Turnkey Solutions: TSM Control Systems offers comprehensive, turnkey solutions for the blown film extrusion process. No other company provides such a holistic approach. Their full-service offerings encompass every step of the process, from raw material preparation to the final product, ensuring seamless integration and optimal performance at every stage.

- Customization: TSM Control Systems recognizes that every end user has unique requirements. To accommodate these, they offer solutions tailored to each customer’s specific needs. This means that their machinery can be adjusted to match the exact requirements of the production process, whether that’s a particular type of plastic, a specific film thickness, or a unique application.

- Adaptable and Flexible Machinery: TSM’s machinery is not just robust and reliable—it’s also highly adaptable. This flexibility means that it can handle a wide range of materials and processes, providing customers with the versatility they need to meet their diverse production demands.

- Cutting-edge Technology: TSM Control Systems is committed to staying at the forefront of technology in the blown film extrusion industry. Their machinery incorporates the latest advances in the field, ensuring that customers benefit from the most efficient, effective, and innovative solutions available.

- Autocleaning: One of the standout features of TSM’s machinery is its autocleaning capability. This feature allows for rapid changes between different recipes without the need to stop the production line or collapse the bubble. This not only speeds up production times but also enhances efficiency. The autocleaning feature provides a significant competitive advantage by reducing downtime and increasing overall productivity.

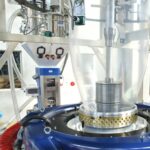

TSM Control Systems, with their unique Gravimetric Batch Blenders, offers a competitive edge in this process, particularly in the context of the emerging circular economy. Here’s how:

- Superior Mixing Homogeneity: TSM’s patented reverse-flight auger mixing technology ensures a high level of mixing homogeneity regardless of the material’s bulk density or geometry. This feature is not commonly found in competing systems, allowing TSM to stand out in the market.

- Increased Efficiency and Flexibility: TSM’s gravimetric blenders offer several benefits, including maximizing the usage of regrind material, producing a consistent end product even with varying feedstocks, reducing process downtime through reliable material blending, and achieving lower scrap rates. These blenders also offer high accuracy dispensing, up to 0.01% of batch, enhancing their efficiency and flexibility.

- Adaptability for Post-Consumer Recyclates: TSM’s blenders can accommodate post-consumer recyclates of varying bulk densities and particle geometries while maintaining a homogeneous mix. This adaptability aligns with the principles of a circular economy, supporting the drive to reduce, reuse, and recycle more plastic materials.

- Support for Sustainability Goals: By facilitating the efficient use of recycled materials, TSM’s blenders contribute to a more sustainable and resource-efficient economy. This is increasingly important as global and political efforts intensify to reduce waste and increase the use of recycled materials in manufacturing processes.

In the context of blown film production, integrating the principles of a circular economy and advanced technologies like gravimetric blending offers significant advantages. It allows for the processing of even low-quality recyclates into functional films, thereby increasing material utilization and reducing waste. Moreover, it can help meet evolving regulatory requirements and appeal to environmentally conscious consumers, thereby enhancing the competitive positioning of companies in the blown film production sector.

Innovative Journey from Plastic to Compostable Film

Highlighted on ‘Ear to the Ground’, this clip showcases how Samco, an Irish agricultural film producer, innovatively navigated an EU directive on single-use plastics. Enabled by TSM Control Systems’ advanced blending technology, Samco replaced traditional oil or polyethylene with compostable Italian resins for faster decomposition. This video stands testament to TSM Control Systems’ role in fostering innovation and environmental responsibility in the industry.

Why Choose TSM Control Systems to assist you in Injection Molding?

Choosing TSM Control Systems to assist in your injection molding process means you’re opting for a partner committed to delivering high-quality, efficient, and sustainable solutions. Here’s why TSM Control Systems stands out as a trusted choice:

- Expertise

- Innovation

- Customization

- Sustainability

- Quality Assurance

- Excellent Customer Support

- Global Presence

By choosing TSM Control Systems, you’re investing in a partnership that brings industry-leading technology, unparalleled expertise, and unwavering support to your injection molding operations. Our mission is to provide you with the tools and solutions that will drive your operational efficiency, product quality, and ultimately, your business success.

Request a Quote

Are you a project engineer looking for a solution which avoids downtime but is customizable to your needs? TSM has the resources for any project, along with the expertise in delivering world class service and support. For quality products delivered on time and in budget, get in touch with TSM today to learn more.