Extrusion Blow Molding

At TSM Control Systems, we understand the importance of flexibility and customization in extrusion blow molding. That’s why we work closely with our clients to develop tailored solutions that meet their unique process requirements and production goals.

Extrusion Blow Molding Solutions

TSM Control Systems is a leading provider of advanced control and automation solutions for a wide range of industrial processes, including extrusion blow molding. With our expertise in gravimetric batch blending. process control and automation, we can help manufacturers optimize their extrusion blow molding processes, improving efficiency, reducing costs, and ensuring consistent, high-quality results.

The extrusion blow molding process can be broken down into several stages:

- Material selection: The first step in upstream works is to select the appropriate material for the product being produced. The most common materials used in extrusion blow molding include high-density polyethylene (HDPE), low-density polyethylene (LDPE), polypropylene (PP), and polyethylene terephthalate (PET).

- Material preparation: Once the material has been selected, it must be prepared for use in the extrusion blow molding process. This typically involves melting and mixing the material with any required additives, such as colorants, stabilizers, or UV inhibitors.

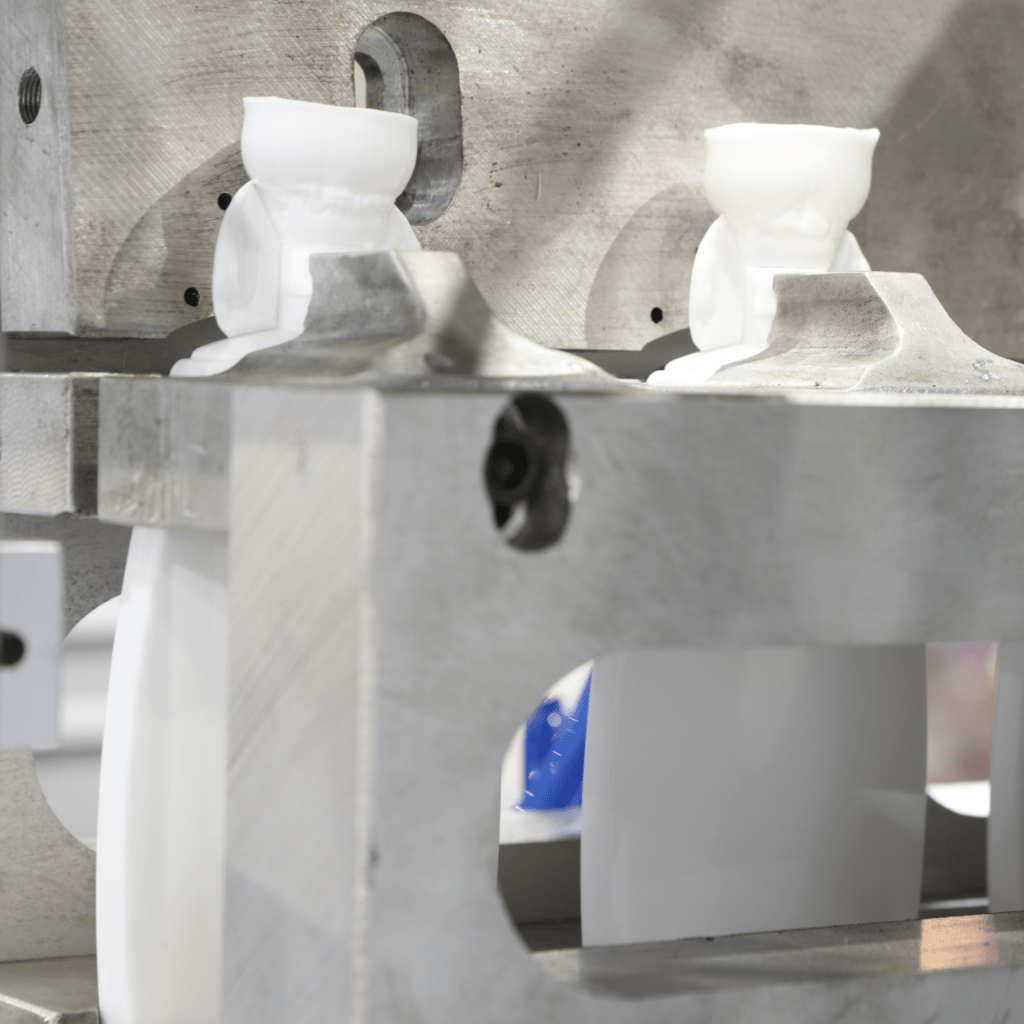

- Extrusion: The first stage involves melting plastic resin in an extruder and forcing it through a die to form a parison. The parison is a tube of molten plastic that has the same cross-section as the finished product.

- Mold Clamping: The mold is closed around the parison, and the two halves of the mold are clamped together.

- Inflation: Compressed air is injected into the parison, causing it to expand and take the shape of the mold.

- Cooling: The plastic is cooled and solidified by the mold.

- Ejection: Once the plastic has cooled and solidified, the mold is opened, and the finished product is ejected.

There is difficulty in recycling the flash and trim waste:

- Trim refers to the excess material that is trimmed off the finished product after it has been molded. This excess material is typically recycled or disposed of.

- Flash, on the other hand, refers to the thin layer of excess plastic that can sometimes form around the edges of the mold during the molding process. This excess material can be trimmed off or removed manually, and is also typically recycled or disposed of.

When the flash and tail are grinded and entered into the process again, they may have different melt flow characteristics than the virgin resin, due to differences in molecular weight, thermal history, and other factors. This can affect the processing behavior and quality of the final product, potentially leading to issues such as reduced strength, dimensional instability, or poor surface finish.

However, TSM solves this problem due to its unique, patented homogenous mixing technology integrated into our blenders.

Surging in plastic extrusion blow molding is an operational issue where the material flow through the extruder becomes irregular or fluctuating:

- This can result in inconsistent wall thickness or poor surface finish in the final product. Surging can also cause defects such as air pockets or voids in the extruded product, which can compromise its quality and performance.

TSM Control Systems’ homogenous mixing technology can help to create a positive downforce that reduces the risk of surging in plastic extrusion blow molding processes.

The mixing screw design used in TSM’s homogenous mixing technology is optimized to create a consistent and uniform melt flow throughout the extruder, which can help to minimize the risk of fluctuations or surges in the flow rate. This can be especially important when using recycled flash and trim materials that may have variability in size, shape, or thickness, which can contribute to surging.

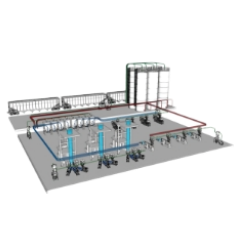

TSM Control Systems Gravimetric Batch Blenders are specifically designed to improve the accuracy, efficiency, and consistency of material blending in extrusion blow molding processes. Here are some ways in which TSM Control Systems Gravimetric Batch Blenders can help in extrusion blow molding:

- Accurate Material Blending: TSM Control Systems Gravimetric Batch Blenders use advanced technology to ensure the accurate measurement and blending of materials. This results in a consistent and homogeneous mixture, improving product quality and reducing material waste.

- Real-Time Monitoring: TSM Control Systems Gravimetric Batch Blenders feature real-time monitoring and control capabilities. This allows operators to quickly identify and correct any issues that may arise during the blending process, minimizing downtime and reducing the risk of product defects.

- Automated Process Control: TSM Control Systems Gravimetric Batch Blenders are fully automated, eliminating the need for manual material weighing and mixing. This reduces the risk of operator error, increases production efficiency, and reduces labor costs.

- Recipe Management: TSM Control Systems Gravimetric Batch Blenders allow for the management of multiple recipes, making it easy to switch between different blends or formulations. This makes it easy to customize products to meet specific customer requirements or production needs.

- Data Collection and Analysis: TSM Control Systems Gravimetric Batch Blenders feature advanced data collection and analysis capabilities. This allows manufacturers to track material usage, monitor blending performance, and identify opportunities for process improvement.

Overall, TSM Control Systems Gravimetric Batch Blenders offer numerous benefits to extrusion blow molding manufacturers. By improving the accuracy, efficiency, and consistency of material blending, these systems can help manufacturers improve product quality, reduce material waste, increase productivity, and improve profitability.

-

Improved accuracy

-

Increased efficiency

-

Flexibility

-

Cost savings

-

Improved quality control

Why Choose TSM Control Systems to assist you in Extrusion Blow Molding

Our state-of-the-art control systems and software solutions are designed to help manufacturers monitor and control every aspect of the extrusion blow molding process, from material handling and melting to parison extrusion, mold clamping, and inflation. By leveraging the power of data analytics and machine learning, we can help manufacturers identify and address process inefficiencies, reduce waste, and improve product quality.

Request a Quote

Are you a project engineer looking for a solution which avoids downtime but is customizable to your needs? TSM has the resources for any project, along with the expertise in delivering world class service and support. For quality products delivered on time and in budget, get in touch with TSM today to learn more.