Wire & Cable Extrusion (Coating)

Unlock the true potential of your wire and cable extrusion process with TSM Control Systems. We offer precision-engineered solutions designed to enhance efficiency, improve product quality, and boost your bottom line. Discover a seamless blend of innovative technology and industry expertise, all tailored to your unique production requirements. Let us be your partner in achieving your manufacturing goals, one cable at a time

Wire & Cable Extrusion (Coating)

At TSM Control Systems, we understand the importance of precision and customization in wire and cable extrusion. We work closely with our clients to develop tailored solutions that meet their unique process requirements and production goals. We offer advanced control and automation solutions for a wide range of industrial processes, including the wire and cable industry.

Wire and cable extrusion is a manufacturing process where a protective or insulating layer is applied to a wire or cable. The materials used in this process often include various plastics, such as polyethylene, polyvinyl chloride (PVC), and thermoplastic elastomers. These products are utilized across numerous industries, including telecommunications, energy, automotive, construction, and electronics.

Key Challenges in Wire and Cable Extrusion

Wire and cable extrusion presents several challenges, including material consistency, process control, color matching, and ensuring consistent insulation thickness. TSM’s solutions are designed to address these challenges, providing improved accuracy, increased efficiency, and better quality control.

Surging in Wire and Cable Extrusion

Surging is an operational issue where the material flow through the extruder becomes irregular or fluctuating. TSM Control Systems’ solutions can help to create a consistent and uniform flow throughout the extruder, reducing the risk of surging in wire and cable extrusion processes.

Our solutions are designed to enhance the wire and cable extrusion process:

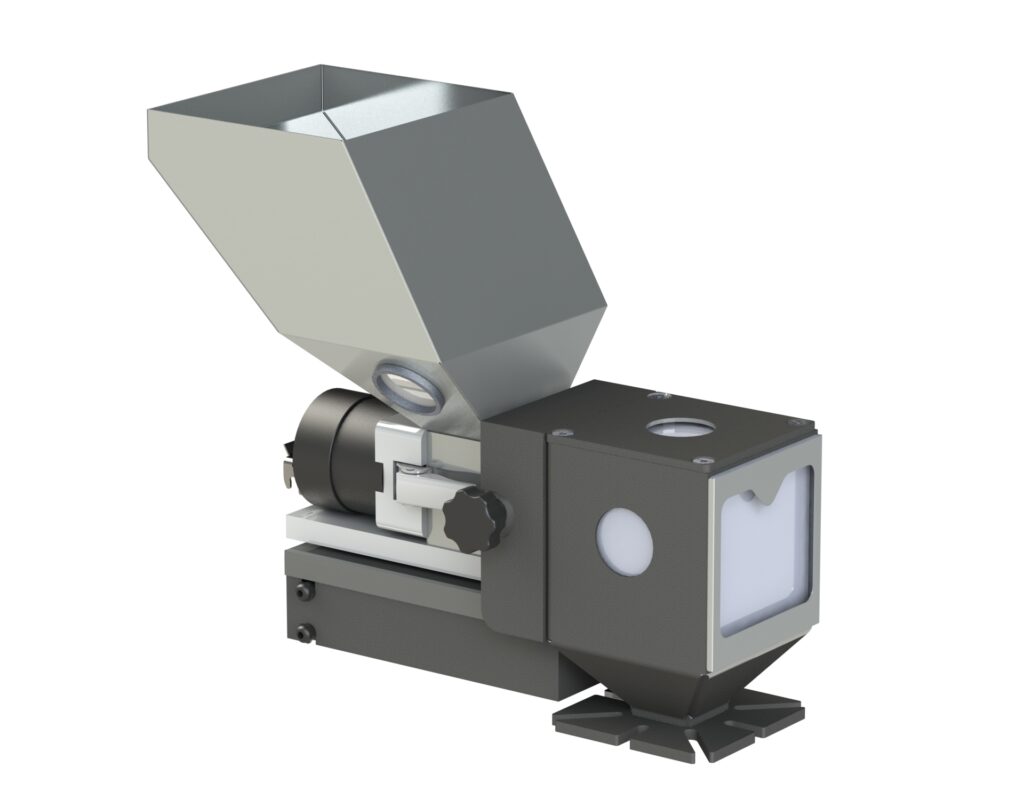

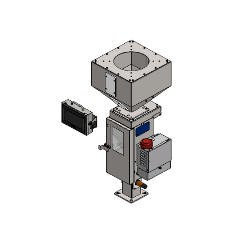

- Opti-Mix Gravimetric Batch Blender: Enhances wire and cable extrusion by providing accurate and uniform mixing of various materials for the insulation layer.

- Opti-Feed SLIW Gravimetric Dosing: Ensures that precise amounts of color and additives are incorporated into the coating material.

- Opti-Yield SLIW Extruder Control: Controls the feed rate of materials into the extrusion process, leading to better quality control and consistency in the final product.

- TSM Conveying, Treatment & Storage Equipment: Efficient handling of materials before, during, and after the extrusion process.

- Opti-Batch Material Totalizer: Measures throughput – material consumption.

- Insight by TSM Control Systems: Offers real-time monitoring and optimization of the production process.

By improving the accuracy, efficiency, and consistency of material blending and processing, TSM Control Systems can help manufacturers improve product quality, reduce material waste, increase productivity, and improve profitability. Our systems also offer flexibility, cost savings, and improved quality control.

Insight by TSM Control Systems

Insight is a platform that offers real-time monitoring and optimization of the production process. It can lead to increased efficiency and quality in wire and cable extrusion. The remote diagnostics, predictive maintenance, and inventory management features can also reduce downtime and streamline the extrusion process.

Partnering for Success

At TSM Control Systems, we believe in the power of partnerships. When you choose us, you’re not just investing in a product or service; you’re becoming part of a team dedicated to the success of your wire and cable extrusion operations. Our experts work closely with you, taking the time to understand your unique needs, challenges, and goals. From there, we develop and implement tailored solutions designed to optimize your process, improve product quality, and maximize efficiency. We provide continuous support and insight, ensuring that our technology evolves with your changing needs. Together, we can turn challenges into opportunities and drive sustainable growth for your business.

Request a Quote

Are you a project engineer looking for a solution which avoids downtime but is customizable to your needs? TSM has the resources for any project, along with the expertise in delivering world class service and support. For quality products delivered on time and in budget, get in touch with TSM today to learn more.