Sheet Extrusion

Unlock the potential of your production with TSM Control Systems. As your trusted partner, we offer a range of machinery to optimize your plastic extrusion process.

Sheet Extrusion

At TSM Controls, we have developed an innovative sheet extrusion process designed to meet the unique demands of various industries. Our process incorporates advanced technologies and is applicable to both standard and cast extrusion methods. We focus on precision, efficiency, and quality, ensuring the optimal performance of your plastic sheet extrusion operations.

TSM Control Systems can help solve these challenges in several ways:

- Material Consistency: TSM’s solutions like the Opti-Mix Gravimetric Batch Blender can help to ensure consistent blending of various materials, leading to a more uniform and high-quality product.

- Equipment Maintenance: TSM’s control systems can monitor equipment performance and signal any unusual readings that might indicate a need for maintenance or part replacement.

- Energy Efficiency: TSM’s control systems optimize the feed rate of materials and the operation of the machinery, potentially reducing energy consumption.

- Waste Management: By ensuring precise control over the material used for extrusion, TSM’s systems can help to reduce material waste.

- Regulatory Compliance: TSM’s solutions are designed to comply with industry standards and regulations. This can help businesses ensure they are meeting their regulatory requirements.

- Technological Advances: TSM stays at the forefront of technology, incorporating the latest advancements into their control systems. This allows businesses to take advantage of innovations that can improve efficiency and productivity.

- Market Competition: By improving the efficiency and quality of the extrusion process, TSM’s solutions can give businesses a competitive edge.

- Product Quality and Consistency: TSM’s Opti-Yield SLIW Extruder Control, for instance, controls the feed rate of materials into the extrusion process, leading to better quality control and consistency in the final product.

- Skilled Labor: TSM’s systems are designed to be user-friendly, reducing the need for extensive training. Moreover, their systems automate many aspects of the process, reducing the reliance on manual labor.

By integrating TSM’s advanced control and automation solutions, businesses can mitigate these challenges and optimize their sheet extrusion process.

We offer a range of solutions designed to enhance every aspect of the sheet extrusion process:

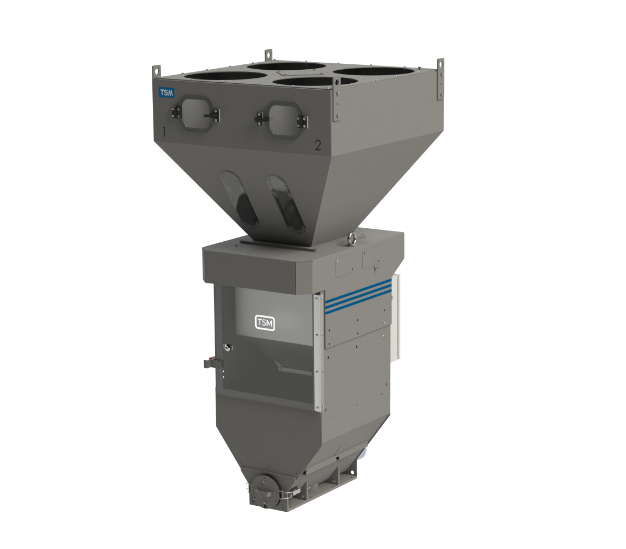

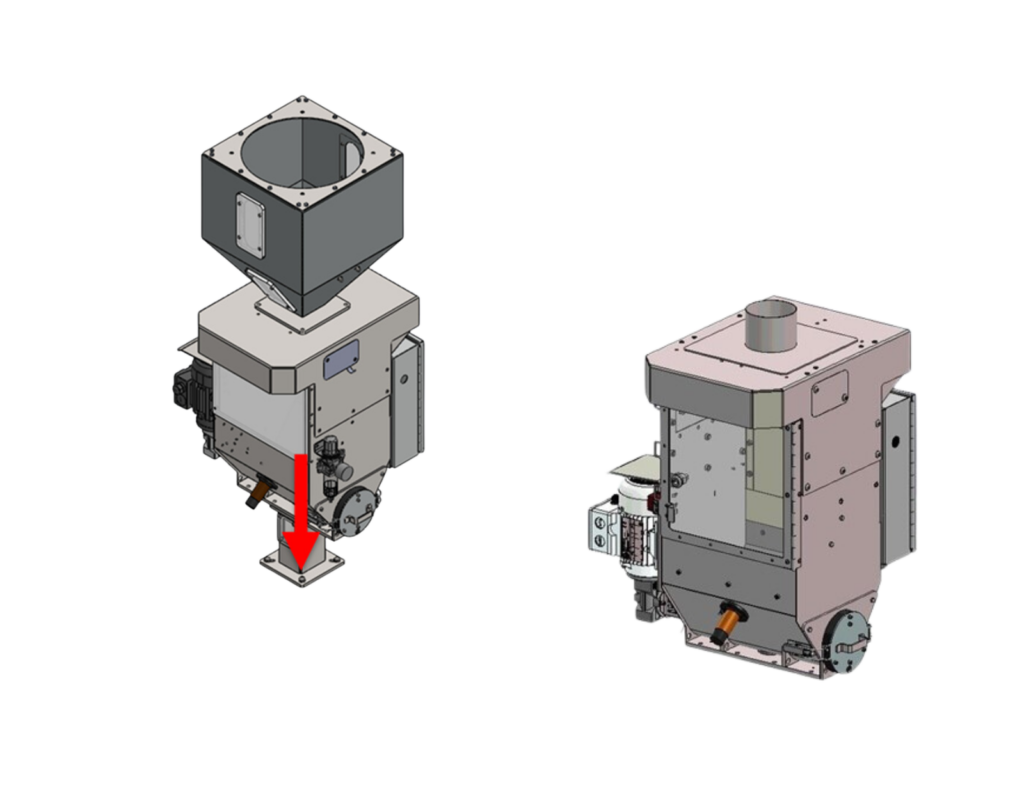

- Opti-Mix Gravimetric Batch Blending: Ensures precise and consistent blending of various materials, enhancing product quality and reducing waste.

- Opti-Flake High Throughput Blender: Designed for high-capacity operations, this blender ensures efficient and uniform blending of materials.

- Opti-Cram Material Feed Assist: Provides reliable material feeding to maintain a consistent flow of material into the extrusion process, enhancing operational efficiency.

- Conveying Systems: Efficient and robust systems for the safe and smooth transportation of materials within your production facility.

- Material Pre-Treatment (Drying): Systems for pre-treating materials, such as drying, to ensure optimal conditions for the extrusion process.

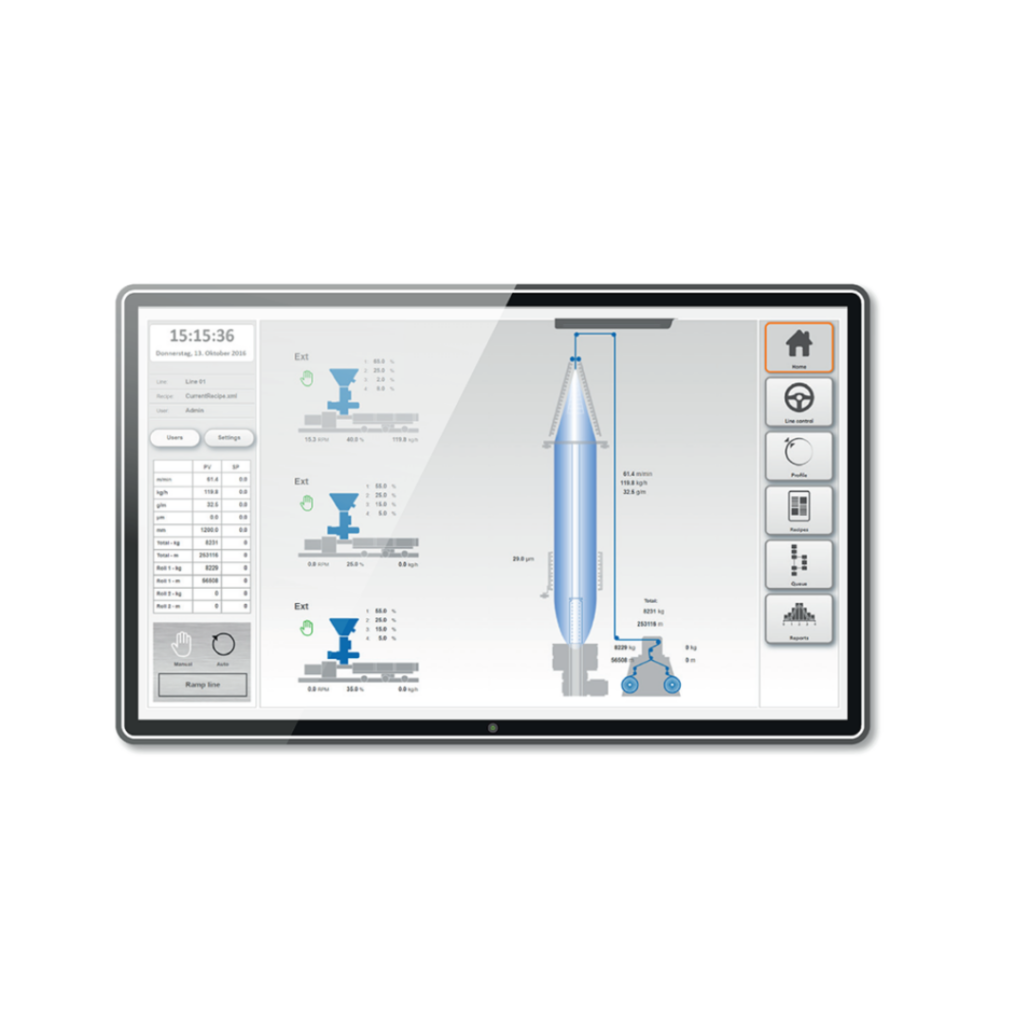

- Supervisory Systems: Advanced systems to monitor and control the extrusion process, ensuring optimal operation and quick identification of any issues.

- Layer Ratio Control: Precise control of layer ratios in multi-layer extrusion processes, ensuring product quality and consistency.

- Automatic Extruder / Yield Control: Systems for automatic control of the extruder and yield, enhancing product quality and reducing waste.

- Insight Realtime Data Collection: Real-time data collection systems providing valuable insights into your extrusion process, enabling data-driven decisions.

- Real Time Industry 4.0 IIoT Data Services: Solutions compatible with Industry 4.0 practices, offering real-time data services for efficient and effective process control.

- Material Consistency: TSM’s solutions, including the Opti-Mix Gravimetric Batch Blender and Opti-Flake High Throughput Blender, ensure precise and consistent blending of various materials. This leads to a more uniform and high-quality product.

- Equipment Maintenance: TSM’s control systems, such as the Supervisory Systems and Automatic Extruder / Yield Control, monitor equipment performance and signal any unusual readings that might indicate a need for maintenance or part replacement.

- Energy Efficiency: TSM’s control systems optimize the feed rate of materials and the operation of the machinery, potentially reducing energy consumption and improving efficiency.

- Waste Management: By ensuring precise control over the material used for extrusion, such as with the Opti-Cram Material Feed Assist, TSM’s systems can help to reduce material waste and increase efficiency.

- Regulatory Compliance: TSM’s solutions are designed to comply with industry standards and regulations. This can help businesses ensure they are meeting their regulatory requirements and maintain high standards in production.

- Technological Advances: TSM stays at the forefront of technology, incorporating the latest advancements into their control systems like Real Time Industry 4.0 IIoT Data Services. This allows businesses to take advantage of innovations that can improve efficiency and productivity.

- Market Competition: By improving the efficiency and quality of the extrusion process with tools like Layer Ratio Control, TSM’s solutions can give businesses a competitive edge and help them stand out in the marketplace.

- Product Quality and Consistency: TSM’s solutions, such as the Opti-Yield SLIW Extruder Control and Insight Realtime Data Collection, ensure better quality control and consistency in the final product.

- Skilled Labor: TSM’s systems are designed to be user-friendly, reducing the need for extensive training. Moreover, their systems automate many aspects of the process, reducing the reliance on manual labor and increasing operational efficiency.

Why Choose TSM Control Systems to assist you in Sheet Extrusion?

Choosing TSM Control Systems to assist in your sheet extrusion process means you’re opting for a partner committed to delivering high-quality, efficient, and sustainable solutions. Here’s why TSM Control Systems stands out as a trusted choice:

- Expertise

- Innovation

- Customization

- Sustainability

- Quality Assurance

- Excellent Customer Support

- Global Presence

By choosing TSM Control Systems, you’re investing in a partnership that brings industry-leading technology, unparalleled expertise, and unwavering support to your injection molding operations. Our mission is to provide you with the tools and solutions that will drive your operational efficiency, product quality, and ultimately, your business success.

Request a Quote

Are you a project engineer looking for a solution which avoids downtime but is customizable to your needs? TSM has the resources for any project, along with the expertise in delivering world class service and support. For quality products delivered on time and in budget, get in touch with TSM today to learn more.