Multifilament Line (Fiber)

Enhance Your Multifilament Line Production with TSM Control Systems. Discover our advanced, customizable solutions designed for precision, efficiency, and superior product quality.

Multifilament Line Solutions by TSM Control Systems

TSM Control Systems is a global leader in providing advanced solutions for the multifilament line production process. Our comprehensive range of products and services are designed to optimize every aspect of your operations, from material handling and blending to real-time data collection and process control.

The multifilament line production process, while offering numerous advantages, also presents a unique set of challenges that manufacturers must address to ensure optimal output and efficiency. Here are some of the key challenges:

- Quality Consistency: Maintaining consistent quality in multifilament lines can be challenging due to variations in materials, manufacturing processes, and environmental conditions. These variations can lead to issues such as line breakage, kinking, and unraveling.

- Durability: Multifilament lines can be susceptible to damage from UV rays, chemicals, and abrasion. Ensuring the durability of the lines is crucial to prevent premature replacement and maintain the integrity of the end products.

- Cost Efficiency: The production of multifilament lines can be more expensive than single-strand fibers, making cost efficiency a significant concern. Manufacturers need to balance the cost of production with the quality and performance of the lines.

- Environmental Impact: The production process can have a negative impact on the environment due to the use of chemicals, energy consumption, and waste generation. Manufacturers are increasingly seeking ways to reduce this impact and make their processes more sustainable.

TSM Control Systems offers a range of solutions designed to address these challenges. Our advanced systems and services help improve quality consistency, enhance durability, reduce costs, and minimize environmental impact, making the multifilament line production process more efficient and sustainable.

- Opti-Mix Gravimetric Batch Blending: Ensures precise and homogeneous blending of materials in batches.

- Opti-Feed SLIW Gravimetric Dosing: Provides precise, weight-based dosing of materials for consistent quality.

- Opti-Yield SLIW Extruder Control: Optimizes the extrusion process by controlling factors like the speed and temperature of the extruder.

- Conveying Systems: Handles the movement of materials in the production process, from raw materials to finished products.

- Material Pre-Treatment (Drying): Prepares raw materials for extrusion, such as drying systems that remove moisture from plastic pellets.

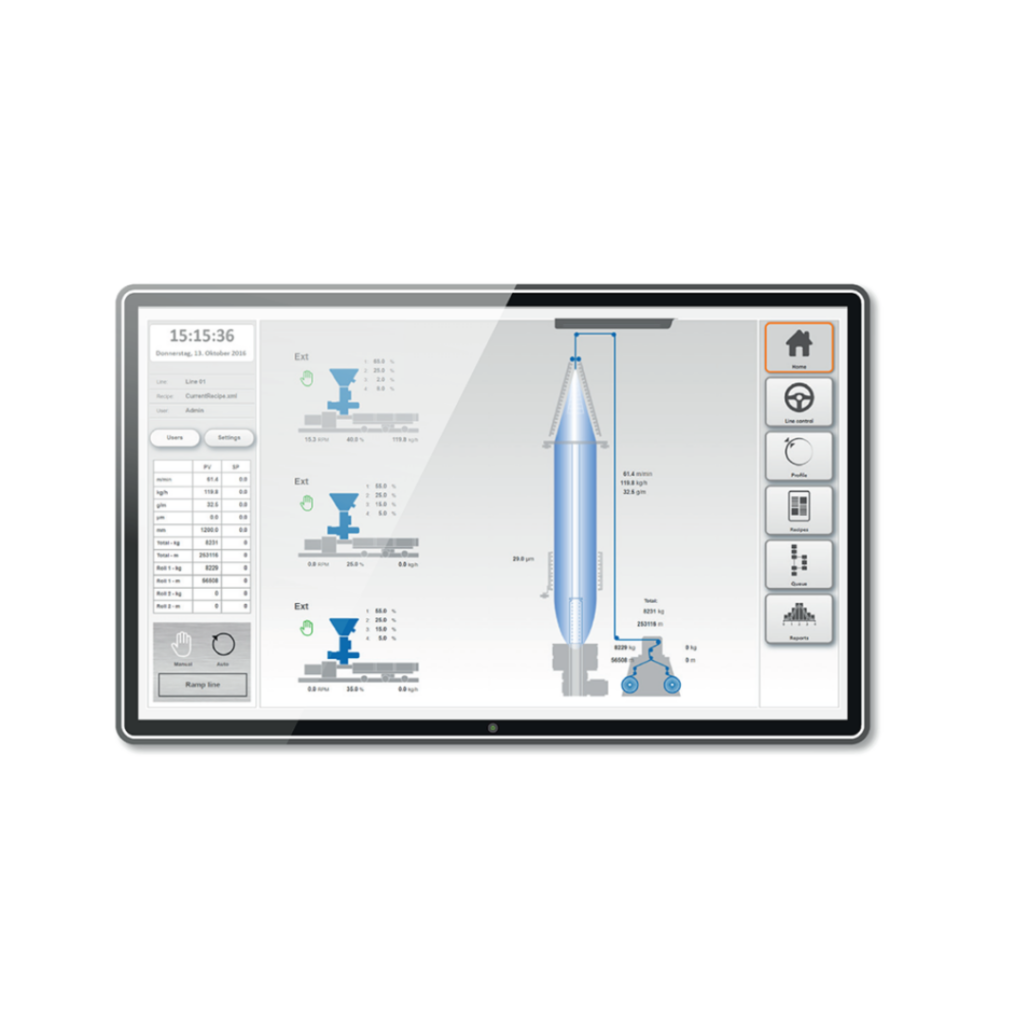

- Supervisory Systems: Oversees and manages the entire production process, including monitoring equipment, scheduling production, and tracking product quality.

- Layer Ratio Control: Controls the thickness of individual layers in a multilayer product, important for producing pipes or profiles with specific properties.

- Automatic Extruder / Yield Control: Automatically adjusts the extrusion process to optimize the yield, or amount of usable product produced.

- Insight Realtime Data Collection: Allows for real-time monitoring and adjustments in the production process, leading to improved efficiency and product quality.

- Real Time Industry 4.0 IIoT Data Services: Advanced, internet-connected systems that collect and analyze data from the production process, providing insights for improving efficiency, reducing waste, and maintaining product quality.

- Customization: TSM Control Systems offers customizable solutions tailored to the specific needs of each client. This means they can adapt their systems to a wide range of applications and requirements, providing a solution that’s the right fit for each individual operation.

- Global Support: With a global presence, TSM Control Systems can provide excellent customer support wherever their clients are located. This includes not only troubleshooting and maintenance but also training and consultation to help clients get the most out of their systems.

- Long-Term Investment: TSM Control Systems’ products are designed for durability and reliability, making them a long-term investment. Their systems are also designed to be upgradeable, so they can adapt to changing needs and technologies.

- Industry Expertise: With many years of experience in the industry, TSM Control Systems has a deep understanding of the challenges and needs of the multifilament line production process. This expertise is reflected in the design of their products and the advice they provide to their clients.

- Innovation: TSM Control Systems is committed to continuous innovation, regularly updating their products and services to incorporate the latest technologies and best practices. This ensures that their clients always have access to the most advanced and efficient solutions available.

- Comprehensive Solutions: TSM Control Systems offers a comprehensive range of products and services, covering all aspects of the multifilament line production process. This means clients can get everything they need from a single, reliable source, simplifying their operations and ensuring that all components work together seamlessly.

Choosing TSM Control Systems for your multifilament line production process means you’re opting for a partner committed to delivering high-quality, efficient, and sustainable solutions. Here’s why TSM Control Systems stands out as a trusted choice:

- Improved Product Quality: Our advanced blending and control systems ensure consistent, high-quality output in the multifilament line production process.

- Enhanced Efficiency: From material handling to extruder control, our solutions are designed to optimize every aspect of the multifilament line production process for maximum efficiency.

- Customizable Solutions: We understand that every operation is unique. Our systems are customizable to meet your specific needs, ensuring the best fit for your process.

- Global Support: With our global presence, we offer excellent customer support wherever you are, ensuring you get the help you need when you need it.

Why Choose TSM Control Systems to assist you in Multifilament Line (Fiber)?

Choosing TSM Control Systems to assist in your Multifilament Line process means you’re opting for a partner committed to delivering high-quality, efficient, and sustainable solutions. Here’s why TSM Control Systems stands out as a trusted choice:

- Expertise

- Innovation

- Customization

- Sustainability

- Quality Assurance

- Excellent Customer Support

- Global Presence

By choosing TSM Control Systems, you’re investing in a partnership that brings industry-leading technology, unparalleled expertise, and unwavering support to your Multifilament Line operations. Our mission is to provide you with the tools and solutions that will drive your operational efficiency, product quality, and ultimately, your business success.

Request a Quote

Are you a project engineer looking for a solution which avoids downtime but is customizable to your needs? TSM has the resources for any project, along with the expertise in delivering world class service and support. For quality products delivered on time and in budget, get in touch with TSM today to learn more.