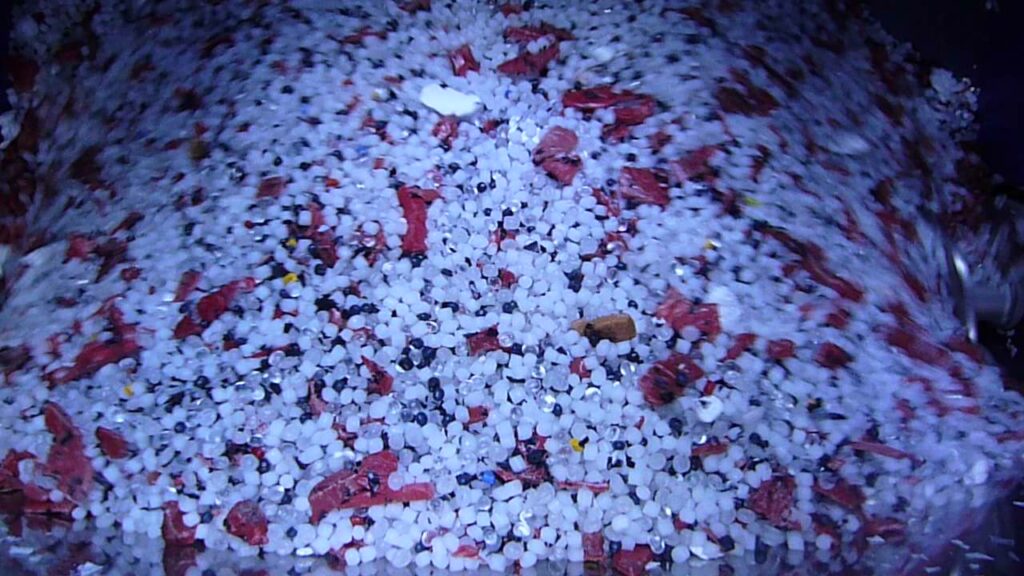

Compounding and Recycling

TSM Control Systems specialize in optimizing compounding and recycling applications, helping processors increase recycled material usage. With precise blending, accurate dosing, efficient conveying, and comprehensive data monitoring, our solutions enable efficient, high-quality production.

Optimizing Compounding and Recycling Applications

At TSM Control Systems, we understand the challenges and demands faced by plastic processors in the compounding and recycling industry. As industries worldwide strive to meet sustainability goals and comply with legislation, including the European Green Deal and circular economy initiatives, the need for effective solutions that increase the proportion of recycled material has never been greater. That’s where TSM Control Systems comes in.

Plastic processors encounter several challenges when it comes to compounding and recycling. Consistent material quality and throughput, efficient material consumption and waste reduction, energy efficiency, environmental considerations, and equipment maintenance are just a few of the obstacles that need to be overcome. Additionally, meeting the increasing demand for recycled plastics while maintaining strict quality standards and competitive pricing poses unique challenges.

Plastic processors encounter several challenges when it comes to compounding and recycling. Consistent material quality and throughput, efficient material consumption and waste reduction, energy efficiency, environmental considerations, and equipment maintenance are just a few of the obstacles that need to be overcome. Additionally, meeting the increasing demand for recycled plastics while maintaining strict quality standards and competitive pricing poses unique challenges.

TSM Control Systems offers a range of innovative solutions designed to help plastic processors increase the proportion of recycled material in their production processes. Our advanced technologies and expertise enable you to optimize your compounding and recycling operations, achieving sustainable and efficient results.

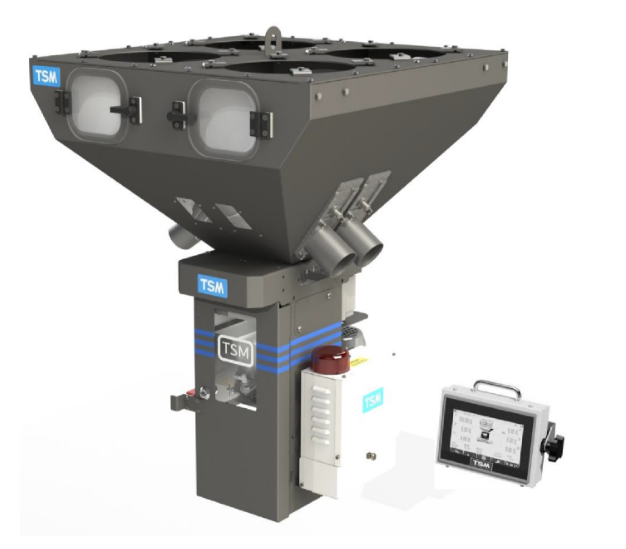

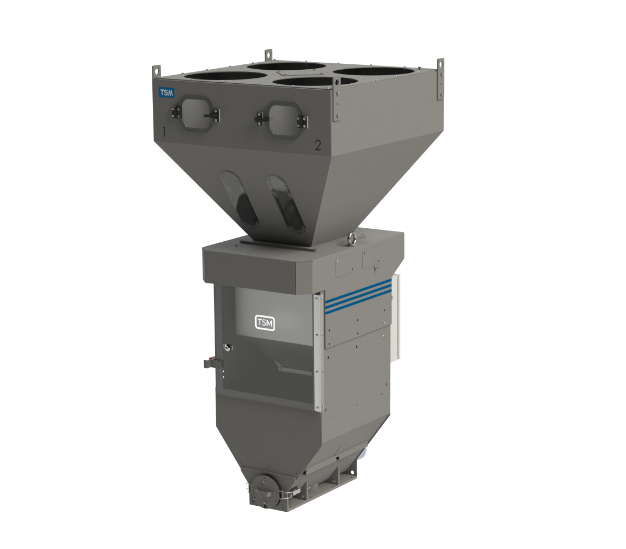

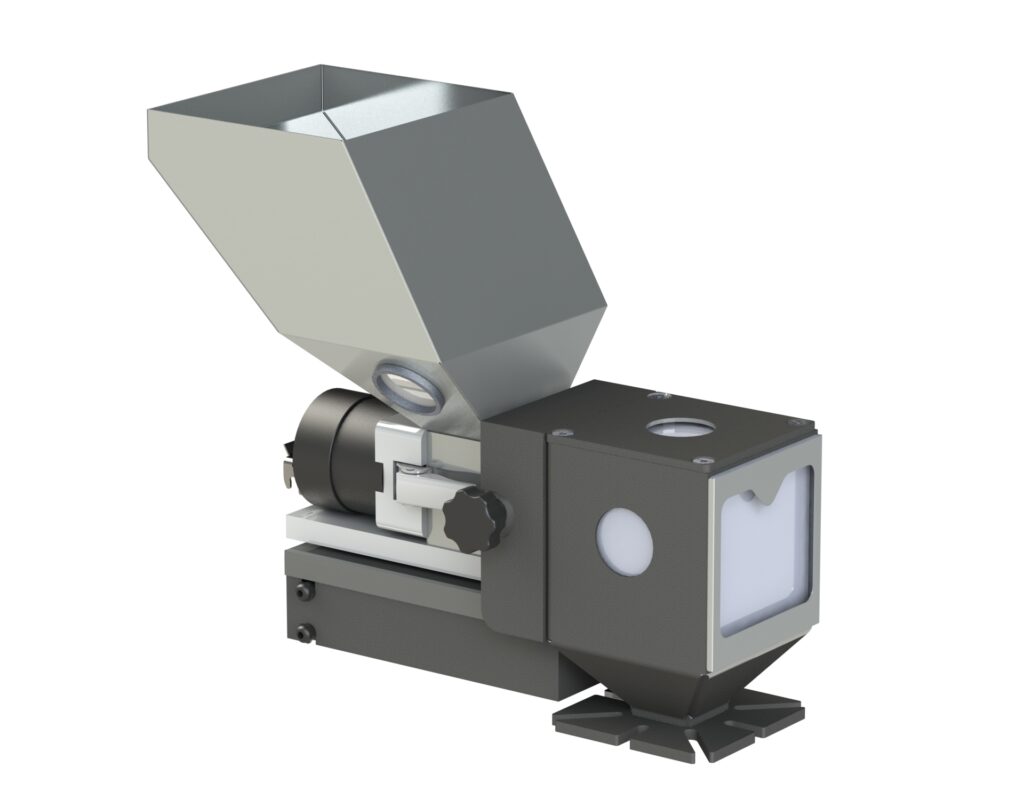

- Opti-Feeder MLIW Continuous Gravimetric Dosing: Our system is specifically designed for starve-fed applications, allowing you to seamlessly incorporate recycled materials while ensuring accuracy and consistency in dosing.

- Opti-Pow Gravimetric Powder Feeder: Ideal for handling recycled powders, this solution provides precise dosing, minimizing waste and maximizing the utilization of recycled materials.

- Conveying Systems: Our conveying systems ensure the efficient handling and transport of recycled materials throughout your production line, optimizing material flow and reducing downtime.

- Material Pre-Treatment (Drying): Our drying solutions are designed to effectively process recycled materials, removing moisture and ensuring optimal material properties for compounding and recycling processes.

- Insight Realtime Data Collection: Monitor and analyze production data in real time with our data collection system, gaining valuable insights into process optimization and quality control.

- Real-Time Industry 4.0 IIoT Data Services: Our advanced connectivity and integration capabilities enable seamless data exchange and integration within your production environment, facilitating enhanced process control and efficiency.

- Enhanced Material Efficiency: Maximize material utilization and minimize waste through accurate dosing and blending, resulting in cost savings and improved operational efficiency.

- Consistent Quality and Throughput: Achieve consistent material quality and uninterrupted production throughput, meeting strict specifications and delivering high-quality end products.

- Improved Energy Efficiency: Optimize energy consumption, reduce environmental impact, and lower carbon footprint by using energy-efficient solutions.

- Seamless Integration and Scalability: Easily integrate our solutions into existing compounding and recycling lines, minimizing disruptions during installation. Our scalable products allow for future expansions or modifications to adapt to evolving business needs.

- Real-time Data Insights: Gain valuable insights into production processes through comprehensive monitoring and analytics, enabling informed decision-making, process optimization, and continuous improvement.

- Industry 4.0 and IIoT Capabilities: Leverage Industry 4.0 principles and IIoT connectivity to remotely monitor, control, and perform predictive maintenance, enhancing operational efficiency, reducing downtime, and improving productivity.

- Precise material blending for consistent quality and efficient utilization.

- Accurate dosing system for reduced waste and optimal material delivery.

- Control system for optimized extrusion processes and material usage.

- Continuous dosing system for uninterrupted production and material efficiency.

- Precise powder feeding for consistent quality and minimal waste.

- Efficient material conveying for streamlined operations and increased productivity.

- Drying systems for proper material preparation and compounding quality.

- Comprehensive data monitoring and analytics for actionable insights and process improvement.

- Connectivity and remote monitoring for enhanced efficiency and predictive maintenance.

By leveraging these benefits and utilizing the advanced features of TSM Control Systems’ solutions, plastic processors in the compounding and recycling industry can achieve sustainable, efficient, and high-quality production processes while contributing to a circular economy and meeting the increasing demand for recycled materials.

Kick Start Your Green Journey & Transform

Your Business Today!

Partnering for Success

With TSM Control Systems as your partner, you can overcome the challenges of compounding and recycling while maximizing the use of recycled materials. Our industry-leading solutions, combined with our expertise and support, ensure that you achieve the highest levels of operational efficiency, quality control, and sustainability.

Join the ranks of successful customers who have witnessed the transformative impact of TSM Control Systems solutions in their compounding and recycling production.

Contact us today to learn more about how TSM Control Systems can optimize your compounding and recycling processes, increase the proportion of recycled material, and help you drive sustainable plastic production in a circular economy.

Request a Quote

Are you a project engineer looking for a solution which avoids downtime but is customizable to your needs? TSM has the resources for any project, along with the expertise in delivering world class service and support. For quality products delivered on time and in budget, get in touch with TSM today to learn more.